CNC 84.00

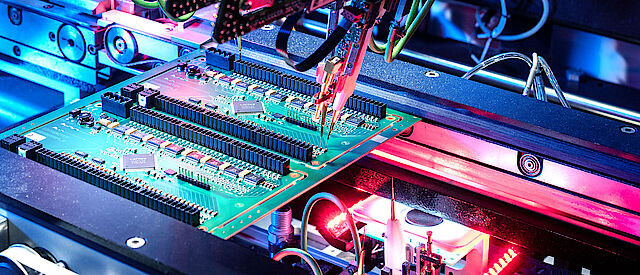

CNC 84.00 - Top Technology for Your Drilling Machine

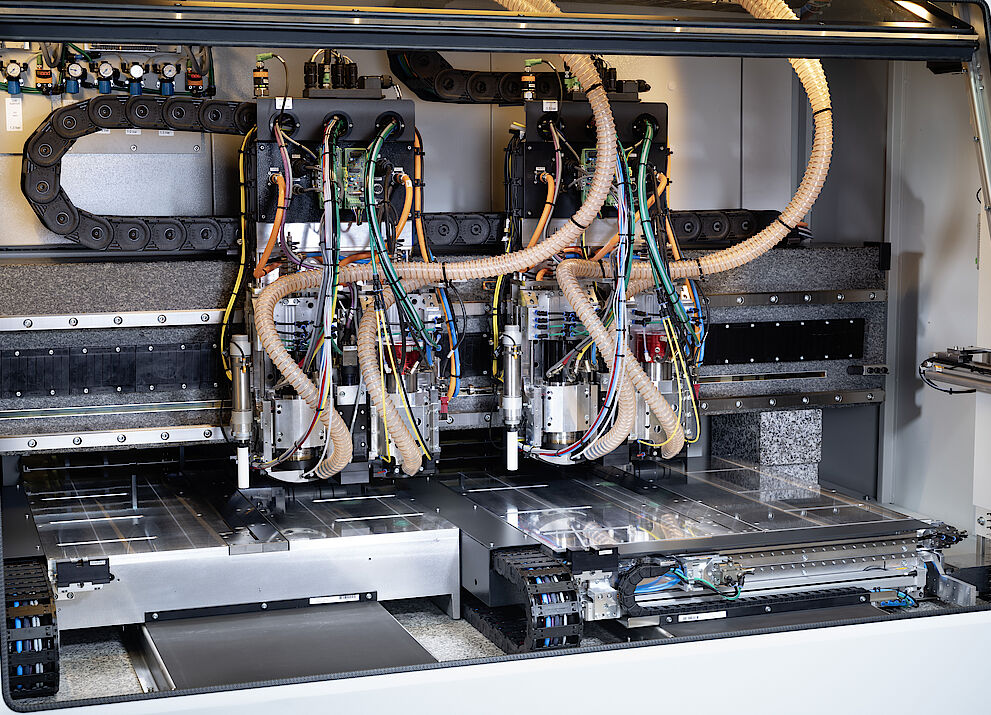

The CNC 84.00 perfectly meets all requirements demanded to a modern CNC for drilling machines in the PCB industry.

The powerful software and hardware of this top CNC allows the highest accuracy, productivity and availability of your drilling machine in the production. The WINDOWS®-based control of the CNC 84.00 is intuitive and easily learnable.

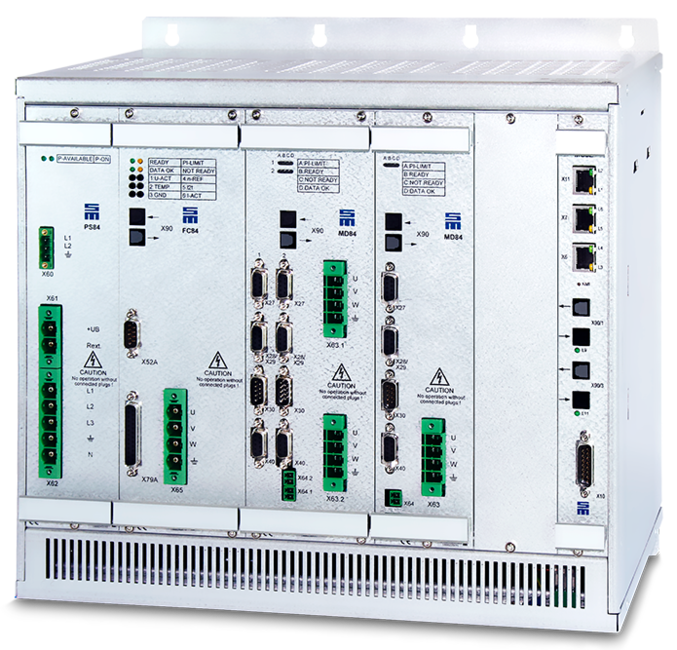

Optimum operation via digital technology

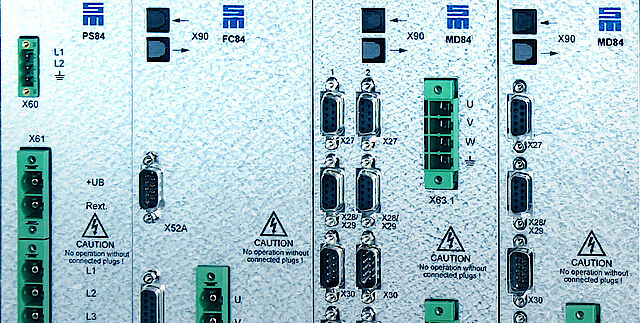

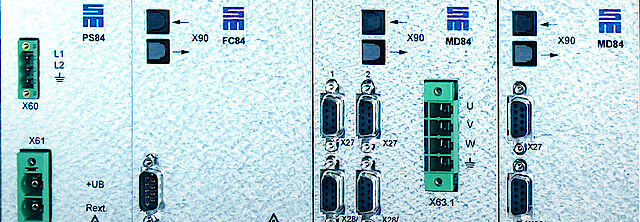

The drive technology of the CNC 84.00 optimized for drilling machines consists of the central Power Supply PS84, the Frequency Converter FC84 for the drilling spindles and the digital servo amplifiers MD84 Nano with position control for very fast and accurate positioning of the machine axes.

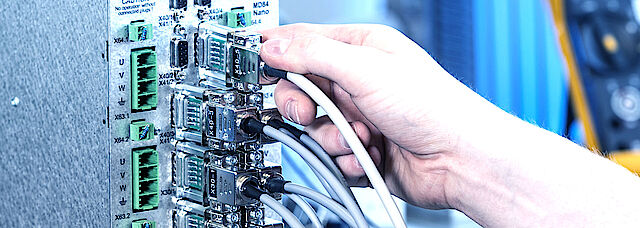

The Frequency Converters FC84 for synchronous and asynchronous spindle motors ensure optimum torque, very short ramp times and keep the heating of the motor as low as possible. All drive modules are easily connected to the Motion Controller MC84 via the fail-safe digital bus SERVOLINK.

High reliability via seperate real-time motion controller

Real-time problems as known from exclusively PC-based systems are reliably excluded by the MC84 in the practice. The PC which is exclusively used as data interface and for visualization communicates with the Motion Controller MC84 via an Ethernet Motion Controller. Furthermore, CNC 84.00 offers a PLC-similar sequential control for the most important machine functions. The new decentral SIEB & MEYER I/O system 84.06 allows easy and time-saving connection via optical fiber cables.

Fast and precise execution of complex drilling programs

The software and hardware of the CNC 84.00 profited of more than 35 years of experience in drilling PCBs. Algorithms and functions, proven thousandfold in the industrial practice, ensure optimal productivity with highest precision.

Surface detection, depth-controlled drilling, graphic display, mapping, Gantry, complex tool management and the operation of synchronous spindles – the CNC 84.00 provides all these features and many more.

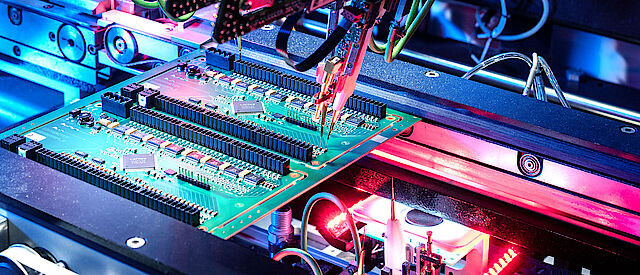

CNC 84.00 - much more than single components

The software and hardware of the CNC 84.00 are perfectly adapted to each other. This ensures fail-safe operation of all interfaces. SIEB & MEYER tests all components of the CNC 84.00 by 100% with high effort under conditions close to production.

SM IIoT CONNECT

With SM IIOT Connect, standard in the CNC 84.00/CNC 82.00 since 2021, the OPC UA server is available as a modern alternative to the previous SMDDE protocol.

The new information model clearly displays all important production parameters and also makes it possible to automate the CNC 84.00/CNC 82.00 using the standardised OPC UA interface. For example, part programmes can be loaded, CNC commands can be sent to the control or processing can be started or stopped.

The interfaces of CNC 84.00

- Mains supply

- Spindles with up to 500,000 1/min

- X and Y drives

- Z drives

- PC

- SERVOLINK

- I/O system 84.06

- Central power supply PS84

- Frequency converter FC84 for synchronous and asynchronous spindles

- Servo amplifiers MD84 Nano for the X and Y axes

- 2 channel motoin drives MD84 Nano for the Z axes

- Motion controller MC84 for positioning and interpolating contour planning

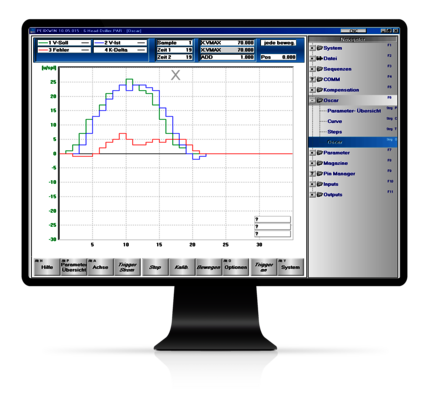

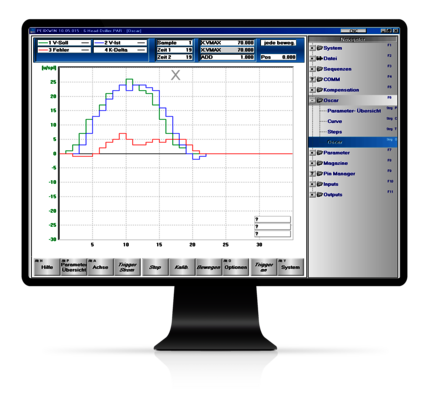

Software for initial operation and parameterization: parameter editor

The parameter editor is a powerful tool for easy and goal-oriented parameterization and optimization of machines.

Parameters set the mechanical characteristics of the machine. Functionalities and sequential behavior of the machine are defined in special sequential programs (sequences). This way any machine type can be adapted to the CNC 84.00 by means of the parameters.

OSCAR is an auxiliary program for optimizing machine movements. By means of the graphic visualization speeds, accelerations, and moving characteristics can be set individually for each axis. This online optimization allows the machine manufacturer to determine the best possible values for a machine and thus achieve considerable improvements in the machine‘s productivity.

Technical Details CNC 84.00

Motion Controller MC84

- Ethernet interface to the PC

- Digital bus via optical fiber cable to the drives MD84, FC84 and to the I/O system 84.06

Servo Amplifiers MD84 Nano with Central Voltage Supply via PS84

- Mains voltage 3 x 230 VAC to 250 VAC

- Single and double-axis design for rotary and linear AC motors

- Evaluation of incremental encoder, absolute encoder or linear measuring system

- Digital bus via optical fiber cable for connection to the MC84

- Rated current Ir: 8.5 Arms to 32 Arms

- Peak current Ip: 23 Arms to 113 Arms

Frequency Converter FC84 with Central Voltage Supply via PS84

Asynchronous spindles:

- Evaluation of speed sensors or operation without sensors

- Rated power: 6 kVA to 15 kVA

- Mains input voltage: 3 x 230/250 VAC, 50/60 Hz

- Rated current Ir: 15 Arms to 29 Arms

- Peak current Ip: 22 Arms to 44 Arms

Synchronous spindles:

- Evaluation of Hall sensors

- Rated power: 2 x 1.2 kVA

- Mains input voltage: 3 x 230/250 VAC, 50/60 Hz

- Rated current Ir: 8 Arms

- Peak current Ip: 14 Arms

Decentral I/O system 84.06

- +24 V DC supply

- Up to 500 inputs and 500 outputs

- Inputs: +24 V (high active)

- Outputs: +24 V, 350 mA

- CRC-controlled data transmission

- Serial interface for external PLC

- PD-Box with integrated interface for tool measurement and tool test

News

Highest Precision for Depth-Controlled Processing of PCBs

SIEB & MEYER Provides Smart SLM Software for Drilling and Routing Machines

CNC 95.00 - The Drive Package

Feel free to contact us

![[Translate to Englisch:] CNC 84.00](/fileadmin/_processed_/f/1/csm_Header_CNC82_84_7c52577360.png)

CNC 84.00

Top Technology for Your Drilling Machine

The CNC 84.00 perfectly meets all requirements demanded to a modern CNC for drilling machines in the PCB industry.

The powerful software and hardware of this top CNC allows the highest accuracy, productivity and availability of your drilling machine in the production. The WINDOWS®-based control of the CNC 84.00 is intuitive and easily learnable.

Optimum operation via digital technology

The drive technology of the CNC 84.00 optimized for drilling machines consists of the central Power Supply PS84, the Frequency Converter FC84 for the drilling spindles and the digital servo amplifiers MD84 Nano with position control for very fast and accurate positioning of the machine axes.

The Frequency Converters FC84 for synchronous and asynchronous spindle motors ensure optimum torque, very short ramp times and keep the heating of the motor as low as possible. All drive modules are easily connected to the Motion Controller MC84 via the fail-safe digital bus SERVOLINK.

High reliability via seperate real-time motion controller

Real-time problems as known from exclusively PC-based systems are reliably excluded by the MC84 in the practice. The PC which is exclusively used as data interface and for visualization communicates with the Motion Controller MC84 via an Ethernet Motion Controller. Furthermore, CNC 84.00 offers a PLC-similar sequential control for the most important machine functions. The new decentral SIEB & MEYER I/O system 84.06 allows easy and time-saving connection via optical fiber cables.

Fast and precise execution of complex drilling programs

The software and hardware of the CNC 84.00 profited of more than 35 years of experience in drilling PCBs. Algorithms and functions, proven thousandfold in the industrial practice, ensure optimal productivity with highest precision.

Surface detection, depth-controlled drilling, graphic display, mapping, Gantry, complex tool management and the operation of synchronous spindles – the CNC 84.00 provides all these features and many more.

CNC 84.00 - much more than single components

The software and hardware of the CNC 84.00 are perfectly adapted to each other. This ensures fail-safe operation of all interfaces. SIEB & MEYER tests all components of the CNC 84.00 by 100% with high effort under conditions close to production.

SM IIoT Connect

![[Translate to Englisch:] CNC 95.00](/fileadmin/_processed_/2/f/csm_Produkt_Teaser-1000x1000_Plattform_64b019ae92.png)

With SM IIOT Connect, standard in the CNC 84.00/CNC 82.00 since 2021, the OPC UA server is available as a modern alternative to the previous SMDDE protocol.

The new information model clearly displays all important production parameters and also makes it possible to automate the CNC 84.00/CNC 82.00 using the standardised OPC UA interface. For example, part programmes can be loaded, CNC commands can be sent to the control or processing can be started or stopped.

The interfaces of CNC 84.00

![[Translate to Englisch:] CNC 84.00](/fileadmin/_processed_/2/e/csm_2500x2500_Schnittstellen_CNC82_84_56619ed912.png)

- Mains supply

- Spindles with up to 500,000 1/min

- X and Y drives

- Z drives

- PC

- SERVOLINK

- I/O system 84.06

- Central power supply PS84

- Frequency converter FC84 for synchronous and asynchronous spindles

- Servo amplifiers MD84 Nano for the X and Y axes

- 2 channel motoin drives MD84 Nano for the Z axes

- Motion controller MC84 for positioning and interpolating contour planning

Software for initial operation and parameterization:

parameter editor

The parameter editor is a powerful tool for easy and goal-oriented parameterization and optimization of machines.

Parameters set the mechanical characteristics of the machine. Functionalities and sequential behavior of the machine are defined in special sequential programs (sequences). This way any machine type can be adapted to the CNC 84.00 by means of the parameters.

OSCAR is an auxiliary program for optimizing machine movements. By means of the graphic visualization speeds, accelerations, and moving characteristics can be set individually for each axis. This online optimization allows the machine manufacturer to determine the best possible values for a machine and thus achieve considerable improvements in the machine‘s productivity.

Technical Details CNC 84.00

Motion Controller MC84

• Ethernet interface to the PC

• Digital bus via optical fiber cable to the drives MD84, FC84 and to the I/O system 84.06

Servo Amplifiers MD84 Nano with

Central Voltage Supply via PS84

• Mains voltage 3 x 230 VAC to 250 VAC

• Single and double-axis design for rotary and linear AC motors

• Evaluation of incremental encoder, absolute encoder or linear measuring system

• Digital bus via optical fiber cable for connection to the MC84

• Rated current Ir: 8.5 Arms to 32 Arms

• Peak current Ip: 23 Arms to 113 Arms

Frequency Converter FC84 with Central Voltage Supply via PS84

Asynchronous spindles:

• Evaluation of speed sensors or operation without sensors

• Rated power: 6 kVA to 15 kVA

• Mains input voltage: 3 x 230/250 VAC, 50/60 Hz

• Rated current Ir: 15 Arms to 29 Arms

• Peak current Ip: 22 Arms to 44 Arms

Synchronous spindles:

• Evaluation of Hall sensors

• Rated power: 2 x 1.2 kVA

• Mains input voltage: 3 x 230/250 VAC, 50/60 Hz

• Rated current Ir: 8 Arms

• Peak current Ip: 14 Arms

Decentral I/O system 84.06

• +24 V DC supply

• Up to 500 inputs and 500 outputs

• Inputs: +24 V (high active)

• Outputs: +24 V, 350 mA

• CRC-controlled data transmission

• Serial interface for external PLC

• PD-Box with integrated interface for tool measurement and tool test

Applications

About Sieb & Meyer

SIEB & MEYER AG - Drive and control solutions of the latest generation

SIEB & MEYER was founded in 1962 and is a successful company in the field of industrial electronics. With around 300 employees worldwide today, we develop and manufacture control technology and drive electronics. Our core technologies include controllers for mechanical engineering and automation technology, servo amplifiers for a wide range of drives and frequency converters for high-speed motors and generators.

Contact

SIEB & MEYER AG

Auf dem Schmaarkamp 21

D-21339 Lüneburg

Phone: +49 4131 203 0

Fax: +49 4131-203 2000

You can find all sales contacts at: www.sieb-meyer.com/contact/sales

You can find all agencies and partners at: www.sieb-meyer.com/contact/offices-and-sales-partners