The optimal products for your dressing application

For dressing applications, it is essential to keep the spindle temperature low: a temperature increase in the spindle causes a longitudinal growth and therefore a shift of the tool position. This must be prevented.

Frequency converters by SIEB & MEYER ensure constant spindle temperatures and can also dynamically control different load situations. Beside a constant temperature, a high speed constancy and the maximum possible torque is important for dressing very hard grinding wheels – factors where the devices by SIEB & MEYER convince all along the line.

Product Overview

| Device series | Power range | Input voltage | Technology | Speed | Type | Communication | Saftey functions |

|---|---|---|---|---|---|---|---|

| SD2B plus | .. 0.8 kVA | 24 .. 80 VDC | 2 Level PWM | 120,000 1/min (2,000 Hz) | Single-axis device | CAN Bus, via Gateway: Profibus, Profinet, EtherCat | STO |

| SD2S | 0.3 .. 55 kVA | 115 .. 480 VAC | 2 Level PWM | 120,000 1/min (2,000 Hz) | Single-axis device | RS232, CAN Bus, EtherCAT, via Gateway: Profibus, Profinet | STO |

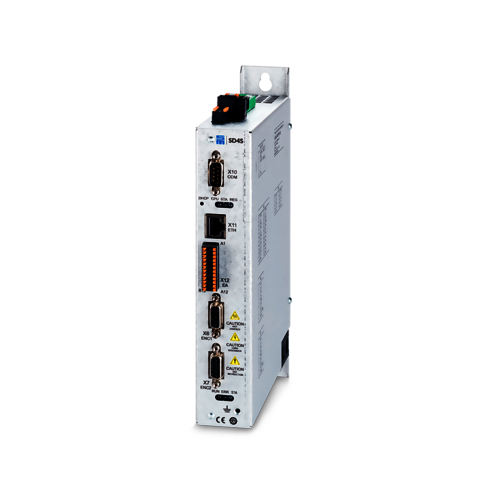

| SD4S | 0.8 .. 66 kVA | 115 .. 480 VAC | 2 Level PWM | 240,000 1/min (4,000 Hz) | Single-axis device | CANopen, EtherCAT, (Profinet, Powerlink) | STO |

| SD4B | ... 0,8 kVA | 24 .. 80 VDC | 2 Level PWM | 240,000 rpm (4,000 Hz) | Single-axis device | RS232/485, CANopen, Modbus TCP, CANopen, EtherCAT. PROFINET, Powerlink in preperation. | STO |

Control systems & drive technology – customized for your application

With our experience from customized drive systems that are meanwhile produced in large series and as well as our standard devices, we are supporting you from the project planning phase to the series production.