Drive controllers for high-speed applications by SIEB & MEYER

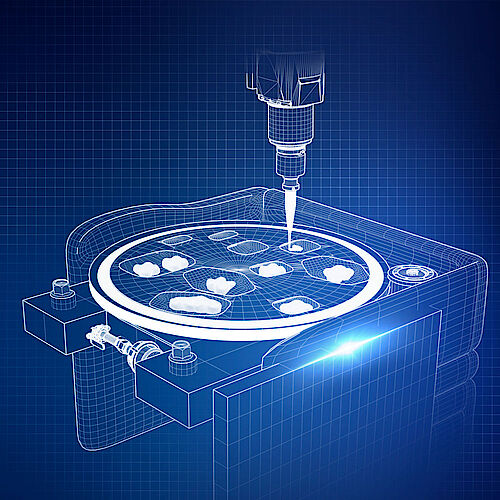

Powerful frequency converters, which provide high rotating field frequencies, are essential for the operation of the high-speed spindles used in modern machine tools. In addition, the usually small rotor volume in the field of high-speed processing requires a highly precise motor control with low losses to prevent excess temperatures. The converters by SIEB & MEYER offer exactly that – with innovative control technology, high energy efficiency and optimized overall efficiency.

Whether used in a large-sized machine tool or in the smallest space of a CAD/CAM milling machine: solutions by SIEB & MEYER guarantee maximum power at minimum heat development. The converters support sensorless and sensor-based operation of synchronous and asynchronous motors with speeds up to 240,000 min⁻¹ – configurable via the intuitive software drivemaster2.

Control systems & drive technology – customized for your application

With our experience from customized drive systems that are meanwhile produced in large series and as well as our standard devices, we are supporting you from the project planning phase to the series production.