The optimal products for your tightening, pressing and clinching applications

Precision is indispensable for tightening applications: If the screw is required to be tightened with a defined torque, the servo amplifier must meet this requirement. Precise regulation and control are also necessary to ensure reproducibility of processes and their documentation, since those tightening applications may involve safety-related tightenings for example in the automotive assembly.

The servo amplifiers by SIEB & MEYER can meet these requirements. Additionally, they support a great variety of motor types and comply with international standards and conventions. Last but not least, the devices convince with their small construction size and a high surge current capability.

In the field of fastening systems, the classic pneumatic or hydraulic systems are often replaced by servo motor driven systems. The advantages of these systems are their adjustable process design, precise process monitoring and documentation, as well as a purely electrical power supply.

Servo amplifiers by SIEB & MEYER enable the highly dynamic operation of servo motors. In addition, the devices provide application-specific interfaces and functions that make it easier to develop a corresponding system. Furthermore, they ensure the highest precision, since the drive solutions by SIEB & MEYER guarantee an optimal control of e.g. the press-in depth and block force.

Product Overview

| Device series | Power range | Input voltage | Motion Controller | Communication | Feedback system | Operating mode | Type |

|---|---|---|---|---|---|---|---|

| SD2 | 1 .. 80 kVA | .. 750 VDC | no | RS485, via Gateway: Profibus, Profinet, EtherCAT | Resolver, Linear-Hall, EnDat2.1, TTL, 1Vss | Speed, torque operation, interpolated position control | Multi-axis system with central power supply unit |

| SD2S | 0.3 .. 55 kVA | .. 480 VAC | no | CANBus, EtherCAT | Resolver, Linear-Hall, EnDat2.1, TTL, 1Vss | Speed, torque operation, interpolated position control | Single-axis device |

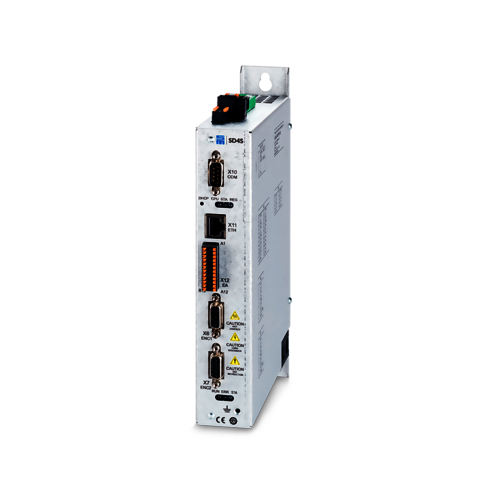

| SD4S | 0.8 .. 66 kVA | 115 .. 480 VAC | no | CANopen, EtherCAT, (Profinet, Powerlink) | Biss-C, EnDat 2.2, TTL, Hall, optional: resolver, SinCos 1 Vss | Speed, torque operation, positioning | Single-axis device |

| Customized | Benefit from our longtime know-how! From the project planning phase to serial production – you get everything from a single source at fast, adjustable and economically viable conditions. | ||||||

Control systems & drive technology – customized for your application

With our experience from customized drive systems that are meanwhile produced in large series and as well as our standard devices, we are supporting you from the project planning phase to the series production.