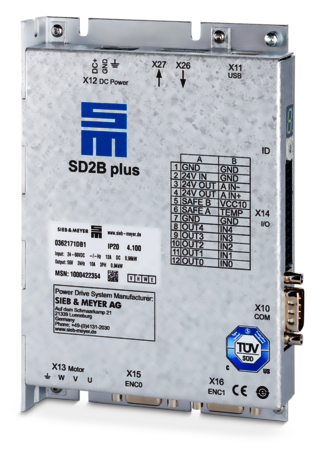

Frequency Converter SD2B plus

The frequency converter SD2B plus allows sensorless operation of low-voltage asynchronous and synchronous motors with speeds up to 120,000 rpm, as well as control with TTL encoders.

Due to this motors can be operated speed-controlled and torque-controlled even from speed zero. The safety function Safe Torque Off (STO) is integrated as standard in the device to allow low-cost realization of the steadily increasing demands towards machine safety.

The NRTL/CSA certified devices are easily integrated into systems for the US market with no additional approvals needed.

Highlights

The space marvel

The IP20 housing of the SD2B plus impresses with a reduced overall height of only 25 mm. The particularly compact design enables simple and flexible integration of the device. In addition to two TTL encoder inputs and outputs, there are five digital inputs/outputs each, an analogue setpoint input and a USB interface for easy parameterisation. All control sequences can also be displayed via the serial bus connections with CAN or RS232 implemented as standard.

![[Translate to Englisch:] Frequenzumrichter SD2plus von Sieb&Meyer](/fileadmin/_processed_/d/9/csm_2500x2500_Schnittstellen_Frequenzumrichter-SD2plus_e4e046a2ba.png)

The Interfaces of Frequency Converter SD2B plus

- USB connection, parameterization, diagnosis and operation

- Analog reference interface +/-10 V

- Safety integrated "STO": Restart lock to meet category 4/PL e according to EN ISO 13849-1:2015 and EN 61508:2010 SIL3

- 5 digital inputs and 5 digital outputs as well as 24 V DC logic power supply

- RS232 / CAN interface

- 2 TTL encoder inputs and outputs

- 2 TTL encoder inputs and outputs / BiSS-Renishaw

- Motor connection

- DC supply

- SERVOLINK

Drive Functions and Safety Functions

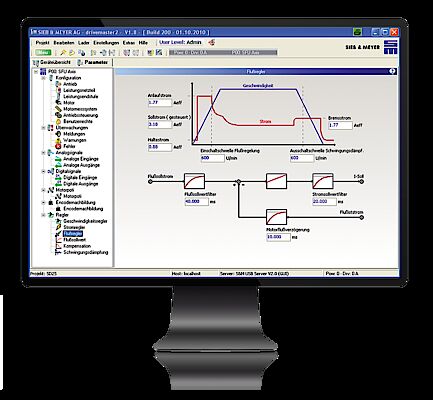

Software for Initial Operation and Parameterization: drivemaster2

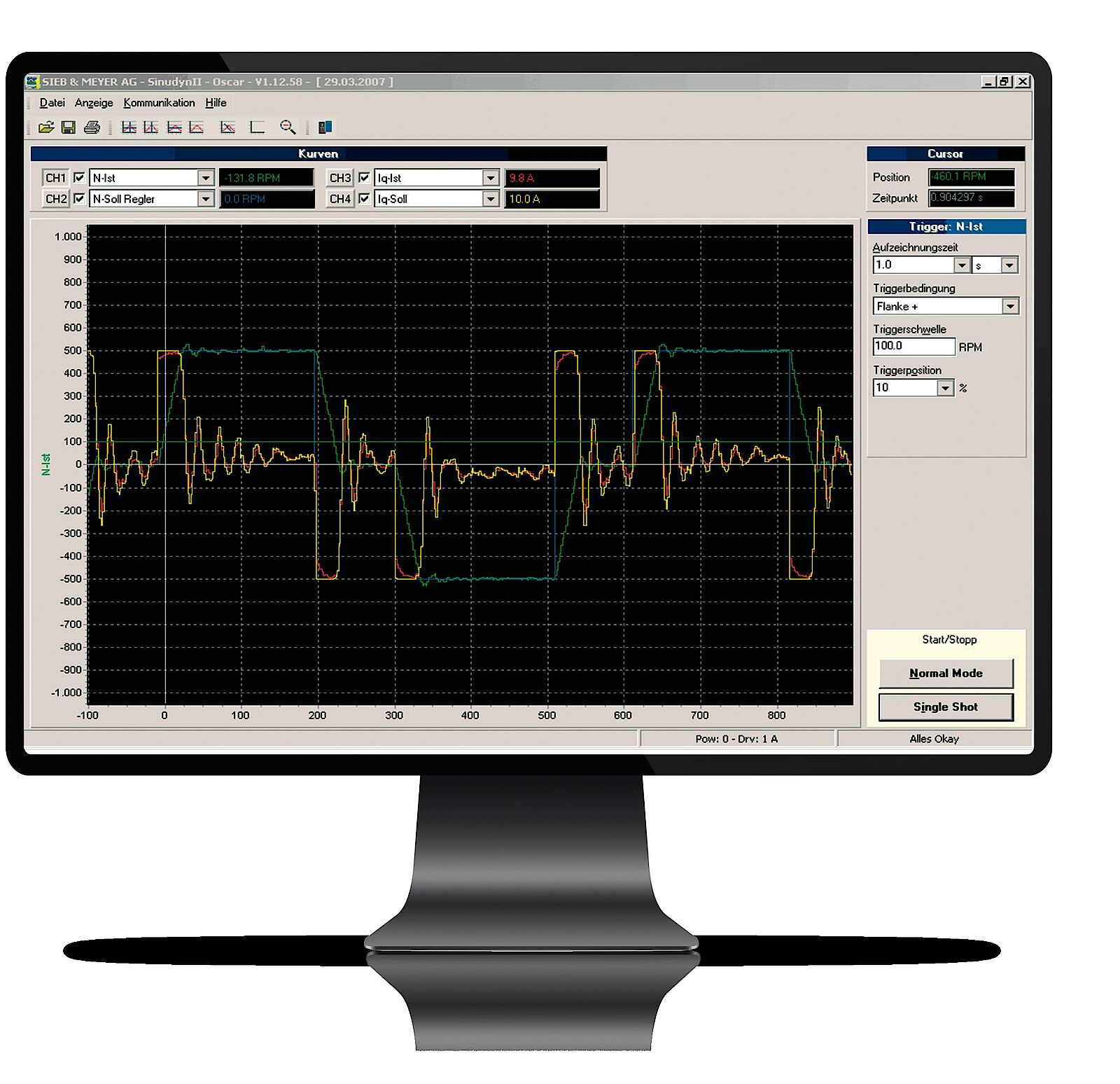

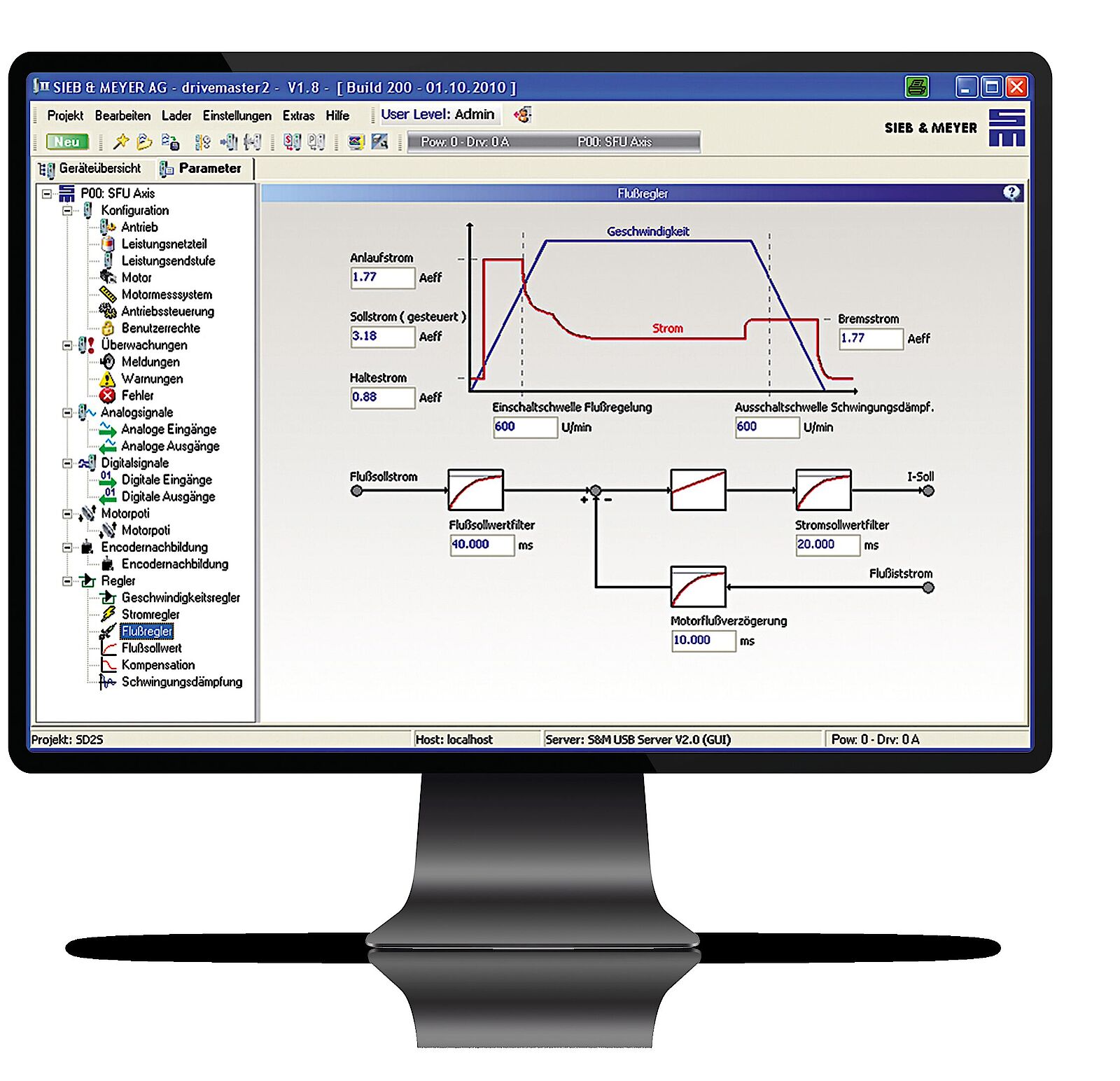

The oscilloscope function allows optimization of the axes in the machine via the drive-setup-tool without additional measuring equipment.

The clear design of the software allows intuitive parameterization via graphics and block diagrams. The „Parameter-Wizard“ guides the user step-by-step through the system configuration and allows intuitive setup of the device via help messages and comments.

Technical Specifications of Frequency Converter SD2B plus

| Device type | Rated power1) | Rated current | Peak current/time | Max. output voltage1) | HxWxD (mm) | Weight | Cooling |

|---|---|---|---|---|---|---|---|

| Device with housing (SD2B plus) - 1 x 24...48 VDC supply voltage | |||||||

| 0362171DA1x 2) | 740 VA | 13 Arms | 15.8 Arms/10 s | 3 x 33 VAC | 165 x 120 x 25 | 0.55 kg | Air |

| Device with housing (SD2B plus) - 1 x 24...80 VDC supply voltage | |||||||

| 0362171DB1x 2) | 940 VA | 10 Arms | 12 Arms/10 s | 3 x 55 VAC | 165 x 120 x 25 | 0.55 kg | Air |

1) Rated power and max. output voltage for mains voltage/supply voltage (in italic)

2) NRTL/CSA certified

News

SIEB & MEYER AG Doubles Sales in 2025

A Drive Controller for All Purposes

Frequency Converters: Past – Present – Future

Feel free to contact us

![[Translate to Englisch:] Frequenzumrichter SD2B plus](/fileadmin/_processed_/9/6/csm_Header_SD2Bplus_dfec167562.png)

Frequency Converter SD2B plus

The frequency converter SD2B plus allows sensorless operation of low-voltage asynchronous and synchronous motors with speeds up to 120,000 rpm, as well as control with TTL encoders.

Due to this motors can be operated speed-controlled and torque-controlled even from speed zero. The safety function Safe Torque Off (STO) is integrated as standard in the device to allow low-cost realization of the steadily increasing demands towards machine safety.

The NRTL/CSA certified devices are easily integrated into systems for the US market with no additional approvals needed.

Highlights

Master-Slave-Operation

- Function: Synchronization of several SD2B plus via TTL encoder inputs and outputs.

- Advantage: Autarkic high-precision synchronization of several SD2B plus frequency converters without external control components.

- Benefit: Lower system costs.

Integrated Logic Voltage Supply

- Function: NRTL/CSA certified.

- Advantage: Easier integration into machines for the North American market.

- Benefit: Lower costs, as no additional approvals are necessary

Parameterization via USB

- Function: Logic voltage supply via USB interface.

- Advantage: Parameterization of SD2B plus without connected voltage supply is possible via the USB interface, which allows pre-configuration of devices outside the machine.

- Benefit: Lower system costs.

The space marvel

The IP20 housing of the SD2B plus impresses with a reduced overall height of only 25 mm. The particularly compact design enables simple and flexible integration of the device.

In addition to two TTL encoder inputs and outputs, there are five digital inputs/outputs each, an analogue setpoint input and a USB interface for easy parameterisation. All control sequences can also be displayed via the serial bus connections with CAN or RS232 implemented as standard.

The Interfaces of Frequency Converter SD2B plus

![[Translate to Englisch:] Frequenzumrichter SD2plus von Sieb&Meyer](/fileadmin/_processed_/d/9/csm_2500x2500_Schnittstellen_Frequenzumrichter-SD2plus_e0dada92de.png)

- USB connection, parameterization, diagnosis and operation

- Analog reference interface +/-10 V

- Safety integrated "STO": Restart lock to meet category 4/PL e according to EN ISO 13849-1:2015 and EN 61508:2010 SIL3

- 5 digital inputs and 5 digital outputs as well as 24 V DC logic power supply

- RS232 / CAN interface

- 2 TTL encoder inputs and outputs

- 2 TTL encoder inputs and outputs / BiSS-Renishaw

- Motor connection

- DC supply

- SERVOLINK

Drive Functions and Safety Functions

Software for Initial Operation and Parameterization: drivemaster2

The oscilloscope function allows optimization of the axes in the machine via the drive-setup-tool without additional measuring equipment.

The clear design of the software allows intuitive parameterization via graphics and block diagrams. The „Parameter-Wizard“ guides the user step-by-step through the system configuration and allows intuitive setup of the device via help messages and comments.

Technical Specifications of Frequency Converter SD2B plus

| Device type | Rated power1) | Rated current | Peak current/time | Max. output voltage1) | HxWxD (mm) | Weight | Cooling |

|---|---|---|---|---|---|---|---|

| Device with housing (SD2B plus) - 1 x 24...48 VDC supply voltage | |||||||

| 0362171DA1x 2) | 740 VA | 13 Arms | 15.8 Arms/10 s | 3 x 33 VAC | 165 x 120 x 25 | 0.55 kg | Air |

| Device with housing (SD2B plus) - 1 x 24...80 VDC supply voltage | |||||||

| 0362171DB1x 2) | 940 VA | 10 Arms | 12 Arms/10 s | 3 x 55 VAC | 165 x 120 x 25 | 0.55 kg | Air |

1) Rated power and max. output voltage for mains voltage/supply voltage (in italic)

2) NRTL/CSA certified

Applications

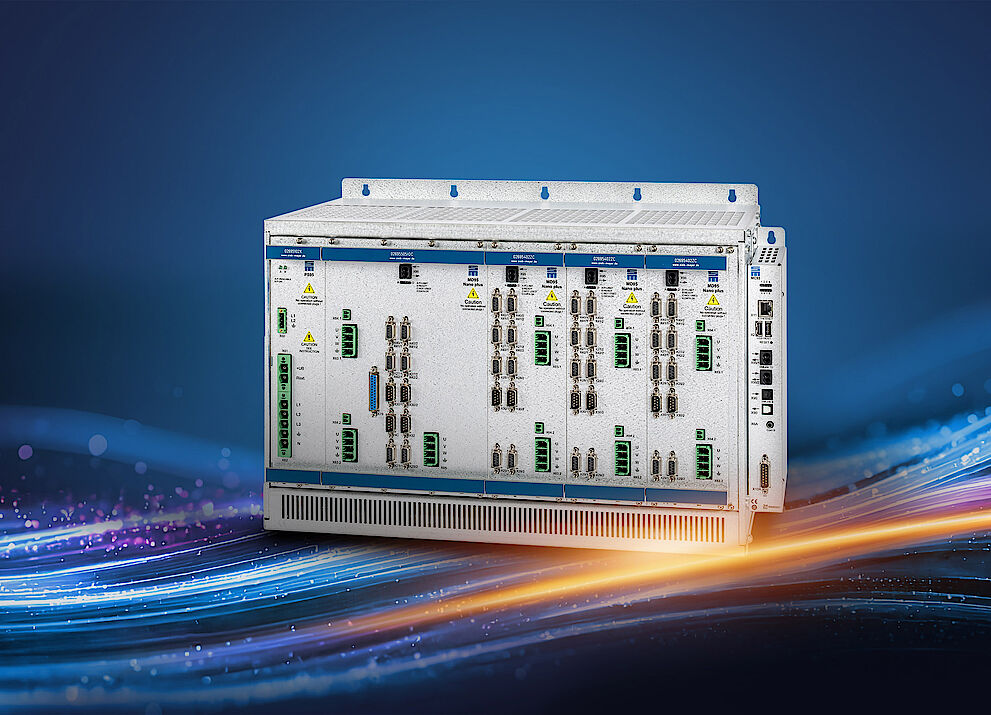

About Sieb & Meyer

SIEB & MEYER AG - Drive and control solutions of the latest generation

SIEB & MEYER was founded in 1962 and is a successful company in the field of industrial electronics. With around 300 employees worldwide today, we develop and manufacture control technology and drive electronics. Our core technologies include controllers for mechanical engineering and automation technology, servo amplifiers for a wide range of drives and frequency converters for high-speed motors and generators.

Contact

SIEB & MEYER AG

Auf dem Schmaarkamp 21

D-21339 Lüneburg

Phone: +49 4131 203 0

Fax: +49 4131-203 2000

You can find all sales contacts at: www.sieb-meyer.com/contact/sales

You can find all agencies and partners at: www.sieb-meyer.com/contact/offices-and-sales-partners