PCD36

Complete Drive System for Scoring Applications

The machine control PCD36 is specially designed for the operation of modern scoring machines used for processing printed circuit boards. The drive package is a modular concept consisting of the motion controller MC2 und several servo amplifiers SD2. Depending on the used motors the assembly of the drive package is variable. A common power supply for all drive amplifiers makes the wiring easy. The energy of the braking axes is fed into the intermediate circuit which saves electricity.

Motion Controller MC2

The drive amplifiers of the positioning axes and the scoring blades are controlled by MC2 via optical fibers. MC2 uses the real-time operating system Linux™/Xenomai. Additionally to the integrated I/Os further input and output modules can be connected. The application software SCORER runs on a standard PC and communicates with MC2 via Ethernet.

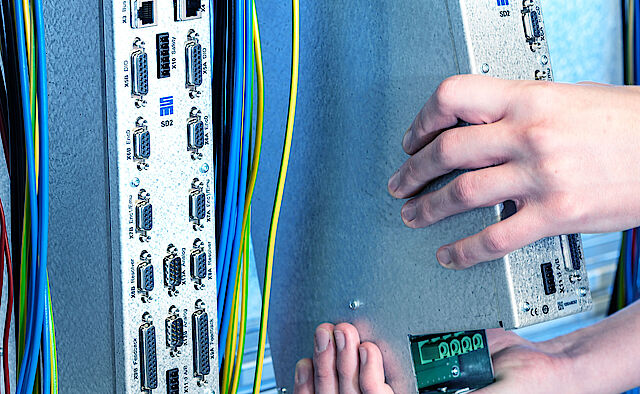

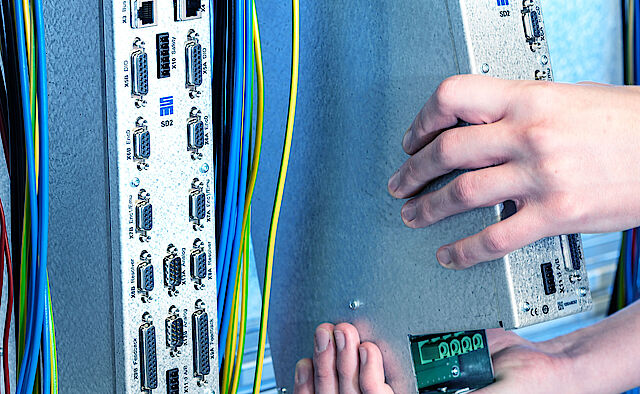

Drive Amplifier SD2

The power supply unit and the drive axes of series SD2 operating as digital servo amplifiers are parameterized with the software drivemaster2. The amplifiers are available as single-axis and double-axis devices with different power ranges and design sizes. Different interfaces enable the connection of rotary and linear motors with all common position measuring systems.

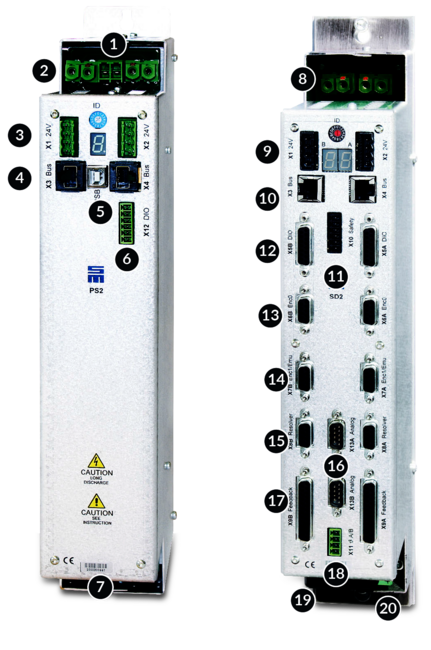

The interfaces of PCD36

- External ballast resistor

- Output DC intermediate circuit voltage

- 24 V logic supply

- Bus input and Bus output

- USB connection

- Digital inputs and outputs

- Mains supply

- Input DC intermediate circuit voltage

- 24 V logic supply

- Parameterization and diagnosis

- Safety Integrated: Restart lock to achieve category 4 according to EN 13849-1:2008-12, EN 62061:2008-04 and EN 61508:2002-11; Safety level SIL 3

- 6 digital inputs and 4 outputs each

- Encoder inputs (pulse-direction signals)

- Encoder outputs (measuring system simulation)

- Resolver inputs

- Analog reference value interfaces: +/-10 V

- Universal Motor Encoder Interface: Resolver, encoder / Linear scale, (TTL or SinCos), EnDat, Hiperface, SSI, Hall effect sensor, linear Hall sensor, magnetoresistive sensors

- Thermal contacts

- 2 x motor connection for linear motors and rotary motors

- SERVOLINK 4 via optical fiber connector

Software for initial operation and parameterization

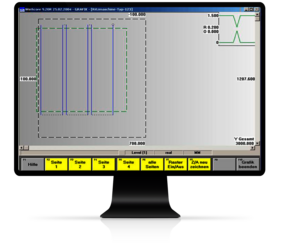

Application Software SCORER

The program SCORER provides a user interface optimized for scoring machines. Additionally to the necessary information for the execution of the scoring process the machine parameters that need to be changed during the execution are entered on the page “tools”. This page is protected by password. The software supports camera measurement of the circuit boards as well as bar code and drill code reader. This way fully automatic operation day and night at highest production precision is guaranteed.

Application Software WINSCORE

Scoring programs can be created with graphic support using the WINSCORE software. Alternatively, programs are loaded from the CAD server via DNC.

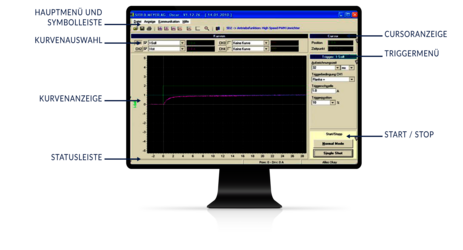

Software drivemaster2

The parameterization and optimization of the drive axes with the software drivemaster2 makes the initial operation of the machine comfortable for the machine manufacturer. Integrated tools for diagnosis and optimization reduce and speed up the necessary work at the machine.

Technical Details PCD36

Main features of PCD36

Complete controller for a scoring machine including:

- Motion Controller MC2

- Power supply for drive axes

- Servo amplifiers

- I/Os

Motion Controller MC2

- Axis processor with real-time operating system

- Ethernet connection

- SERVOLINK – Optical fiber connection to the servo amplifiers

- Internal digital inputs and outputs

- IO LINK – Optical fiber connection to additional inputs and outputs

- SD card memory

Digital Servo Amplifiers SD2

- Integrated safety level SIL 3

- Digital inputs and outputs

- Evaluation of two measuring systems per amplifier

- Measuring system output

- Measuring systems:

- Resolver

- Rotary encoder TTL

- Linear scale, Sin/Cos or TTL

- SSI

- Hiperface

- Rated current: 10 Arms*

- Peak current: up to 85 Arms *

I/O System

- Integrated inputs and outputs

- Expandable up to 128 inputs and 128 outputs via IO LINK (optical fibers)

- External PLC or soft PLC possible

* Dependent on used module version

Measurements: Dependent on configuration

Feel free to contact us

![[Translate to Englisch:] Maschinensteuerung PCD36](/fileadmin/_processed_/1/f/csm_Header_SPCD36_d32cecbc93.png)

PCD36

Complete Drive System for Scoring Applications

The machine control PCD36 is specially designed for the operation of modern scoring machines used for processing printed circuit boards. The drive package is a modular concept consisting of the motion controller MC2 und several servo amplifiers SD2. Depending on the used motors the assembly of the drive package is variable. A common power supply for all drive amplifiers makes the wiring easy. The energy of the braking axes is fed into the intermediate circuit which saves electricity.

Motion Controller MC2

The drive amplifiers of the positioning axes and the scoring blades are controlled by MC2 via optical fibers. MC2 uses the real-time operating system Linux™/Xenomai. Additionally to the integrated I/Os further input and output modules can be connected. The application software SCORER runs on a standard PC and communicates with MC2 via Ethernet.

Drive Amplifier SD2

The power supply unit and the drive axes of series SD2 operating as digital servo amplifiers are parameterized with the software drivemaster2. The amplifiers are available as single-axis and double-axis devices with different power ranges and design sizes. Different interfaces enable the connection of rotary and linear motors with all common position measuring systems..

The interfaces of PCD36

![[Translate to Englisch:] Maschinensteuerung PCD36](/fileadmin/_processed_/e/2/csm_2500x2500_Schnittstellen_PCD36_ada073b013.png)

- External ballast resistor

- Output DC intermediate circuit voltage

- 24 V logic supply

- Bus input and Bus output

- USB connection

- Digital inputs and outputs

- Mains supply

- Input DC intermediate circuit voltage

- 24 V logic supply

- Parameterization and diagnosis

- Safety Integrated: Restart lock to achieve category 4 according to EN 13849-1:2008-12, EN 62061:2008-04 and EN 61508:2002-11; Safety level SIL 3

- 6 digital inputs and 4 outputs each

- Encoder inputs (pulse-direction signals)

- Encoder outputs (measuring system simulation)

- Resolver inputs

- Analog reference value interfaces: +/-10 V

- Universal Motor Encoder Interface: Resolver, encoder / Linear scale, (TTL or SinCos), EnDat, Hiperface, SSI, Hall effect sensor, linear Hall sensor, magnetoresistive sensors

- Thermal contacts

- 2 x motor connection for linear motors and rotary motors

- SERVOLINK 4 via optical fiber connector

Software for initial operation and parameterization

Application Software SCORER

The program SCORER provides a user interface optimized for scoring machines. Additionally to the necessary information for the execution of the scoring process the machine parameters that need to be changed during the execution are entered on the page “tools”. This page is protected by password. The software supports camera measurement of the circuit boards as well as bar code and drill code reader. This way fully automatic operation day and night at highest production precision is guaranteed.

Application Software WINSCORE

Scoring programs can be created with graphic support using the WINSCORE software. Alternatively, programs are loaded from the CAD server via DNC.

Software drivemaster2

The parameterization and optimization of the drive axes with the software drivemaster2 makes the initial operation of the machine comfortable for the machine manufacturer. Integrated tools for diagnosis and optimization reduce and speed up the necessary work at the machine.

Technical Details PCD36

Main features of PCD36

Complete controller for a scoring machine including:

• Motion Controller MC2

• Power supply for drive axes

• Servo amplifiers

• I/Os

Motion Controller MC2

• Axis processor with real-time operating system

• Ethernet connection

• SERVOLINK – Optical fiber connection to the servo amplifiers

• Internal digital inputs and outputs

• IO LINK – Optical fiber connection to additional inputs and outputs

• SD card memory

Digital Servo Amplifiers SD2

• Integrated safety level SIL 3

• Digital inputs and outputs

• Evaluation of two measuring systems per amplifier

• Measuring system output

• Measuring systems:

- Resolver

- Rotary encoder TTL

- Linear scale, Sin/Cos or TTL

- SSI

- Hiperface

• Rated current: 10 Arms*

• Peak current: up to 85 Arms *

I/O System

• Integrated inputs and outpu

• Expandable up to 128 inputs and 128 outputs via IO LINK (optical fibers)

• External PLC or soft PLC possible

* Dependent on used module version

Measurements: Dependent on configuration

Anwendungen

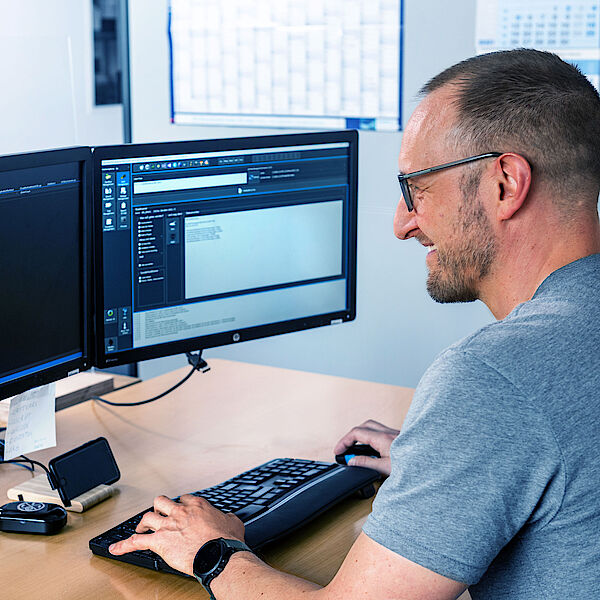

About Sieb & Meyer

SIEB & MEYER AG - Drive and control solutions of the latest generation

SIEB & MEYER was founded in 1962 and is a successful company in the field of industrial electronics. With around 300 employees worldwide today, we develop and manufacture control technology and drive electronics. Our core technologies include controllers for mechanical engineering and automation technology, servo amplifiers for a wide range of drives and frequency converters for high-speed motors and generators.

Contact

SIEB & MEYER AG

Auf dem Schmaarkamp 21

D-21339 Lüneburg

Phone: +49 4131 203 0

Fax: +49 4131-203 2000

You can find all sales contacts at: www.sieb-meyer.com/contact/sales

You can find all agencies and partners at: www.sieb-meyer.com/contact/offices-and-sales-partners