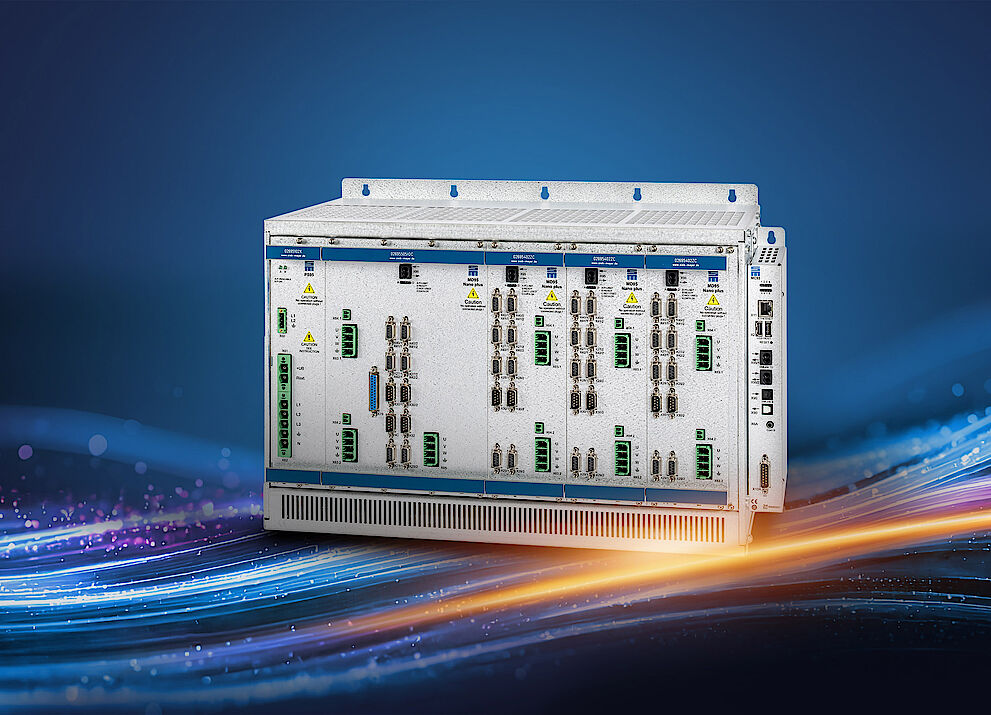

Frequency Converter SD4M

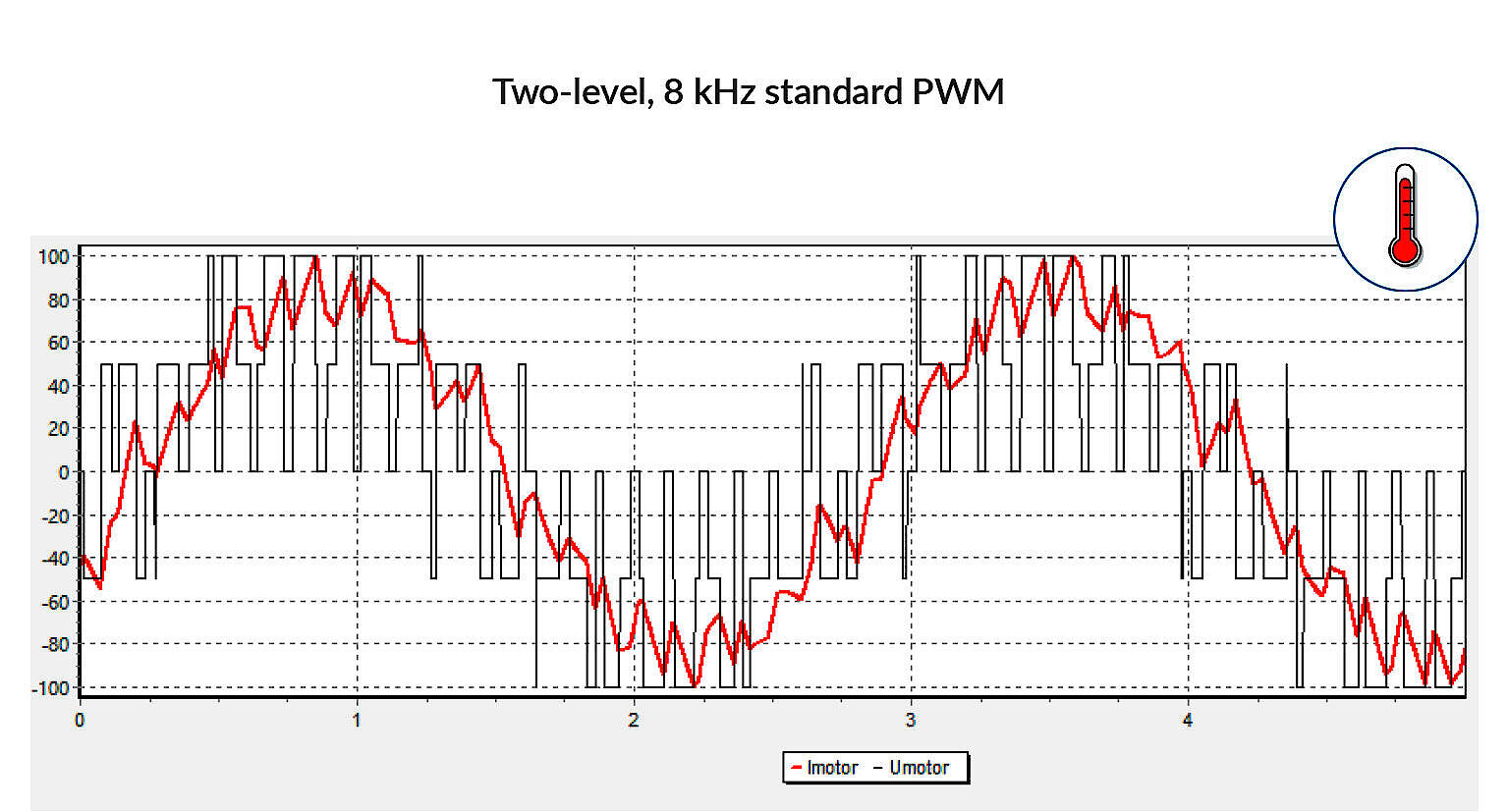

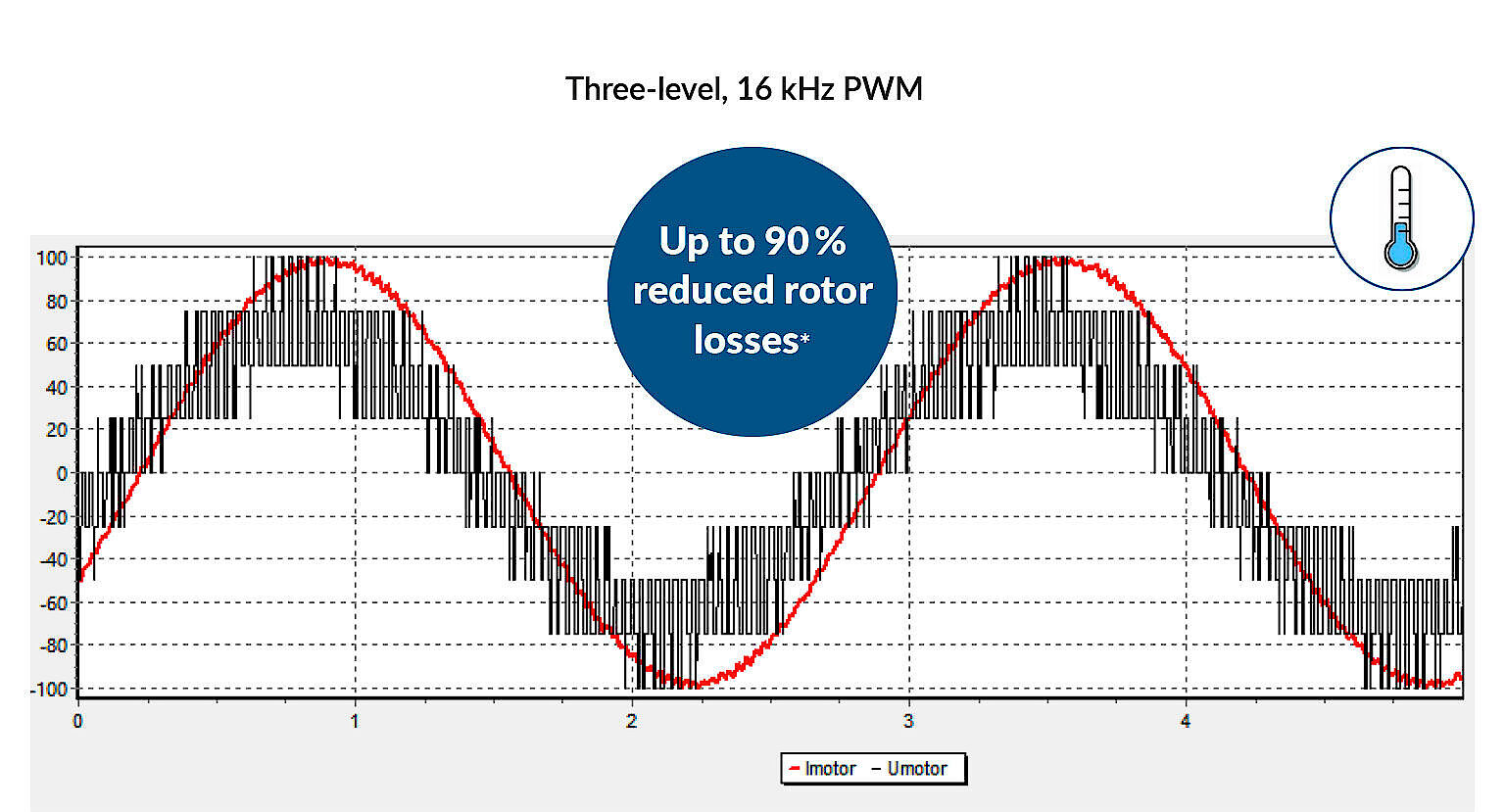

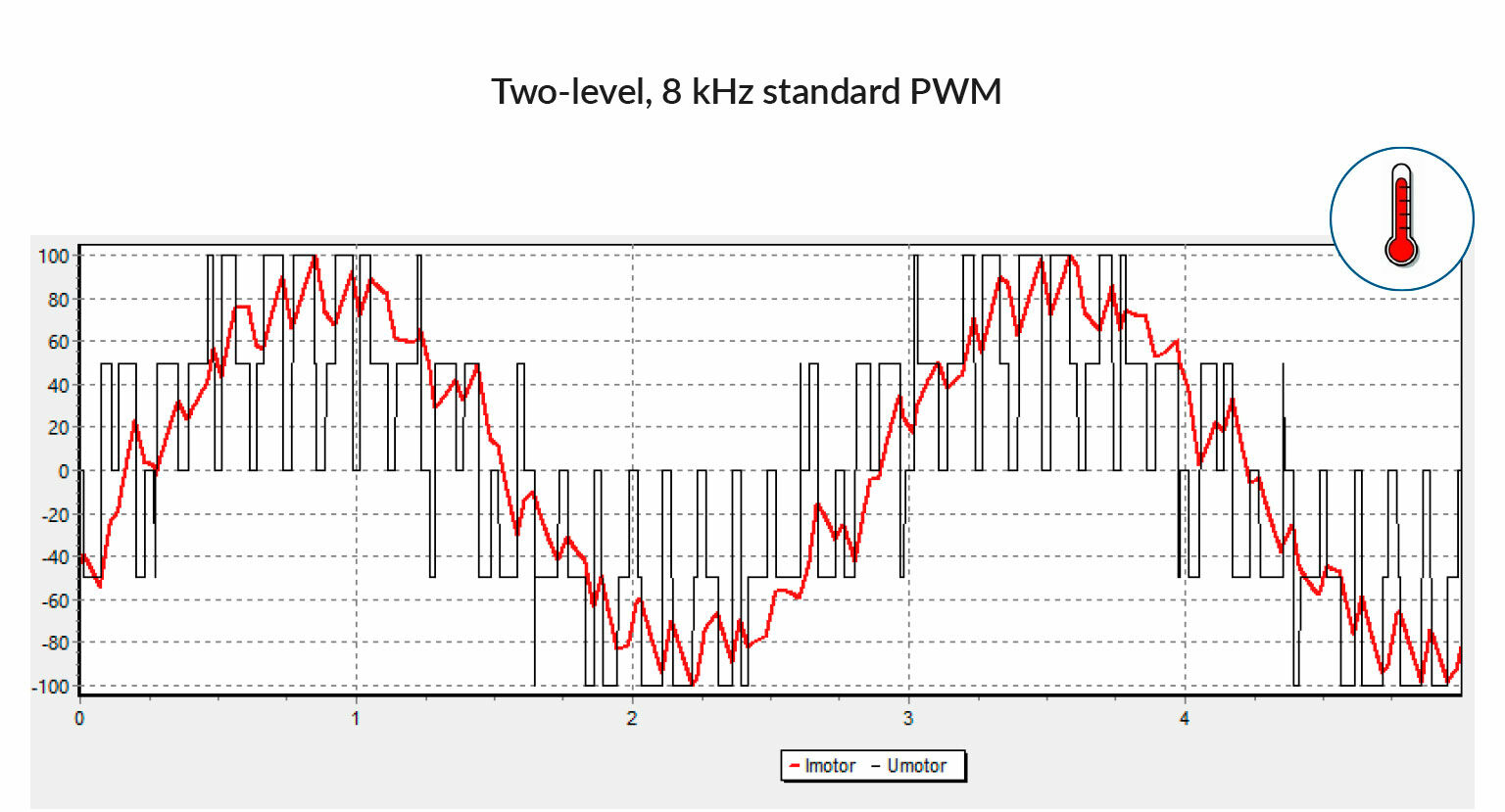

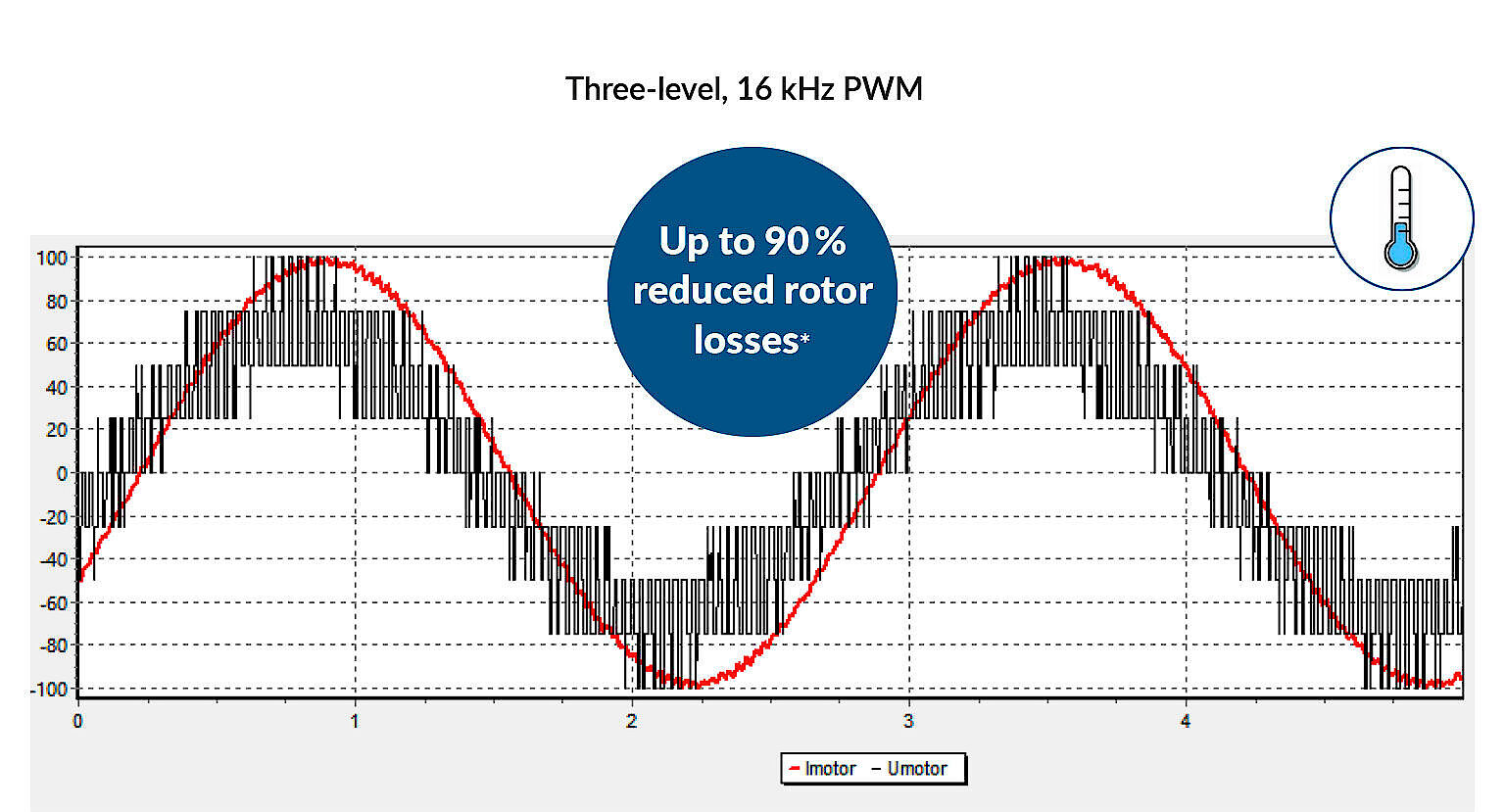

Standard converters in the higher power classes typically use the well-known technology of two-level pulse width modulation (PWM) with max. 8 kHz switching frequency. In most high-speed applications, this requires additional components such as LC filters or chokes to minimize the additional losses in the engine. SIEB & MEYER frequency converters of series SD4M are specially designed for high-speed applications and use the innovative three-level technology – also called multi-level technology.

The SD4M devices follow the successful SD2M series and are designed for stationary use in control cabinets of turbo compressors as well as for applications such as ORC, gas expansion and flywheel.

The Top Booster

The three-level technology is of great advantage in these applications because in most cases the SD4M converters do not require motor filter elements. This additional value is achieved by the three-level technology, as well as the PWM switching frequency of up to 16 kHz as standard and optionally up to 32 kHz for dedicated versions. The combination leads to a considerably improved motor current quality, which significantly reduces the undesired rotor losses – by up to 90 %!

| Technology/ System-Property | SD4M Three-level PWM | Standard converter Two-level PWM with motor choke | Standard converter Two-level PWM with LC filter |

|---|---|---|---|

| Low weight | ✓ | X | X |

| Small installation space | ✓ | X | X |

| No risk of resonance effects | ✓ | ✓ | X |

| Total costs | ✓ | X | X |

Highlights

Our Experience in High-speed Technology - Your Advantage!

Up to 60 % reduced installation space for the required electrical components

Improved availability due to the reduced number of components

Up to 50 % reduced weight for the required electrical component

Reduced environmental footprint due to lower energy consumption

Significantly less wiring- and assembly work

Connectivity for the future Ethernet/web server/EtherCAT/Modbus

Cost reduction for the drive chain

Maximum performance of IPM motors through dynamic operating point control

Improved efficiency of the overall system

Motor Currents by Comparison

Good to Know

- Currently available power classes from 100 to 500 kVA, with up to 800 Aeff rated current.

- Liquid cooling as standard (water-based), air cooling on request

- NRTL/CSA certified

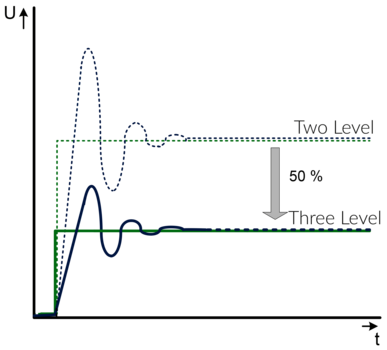

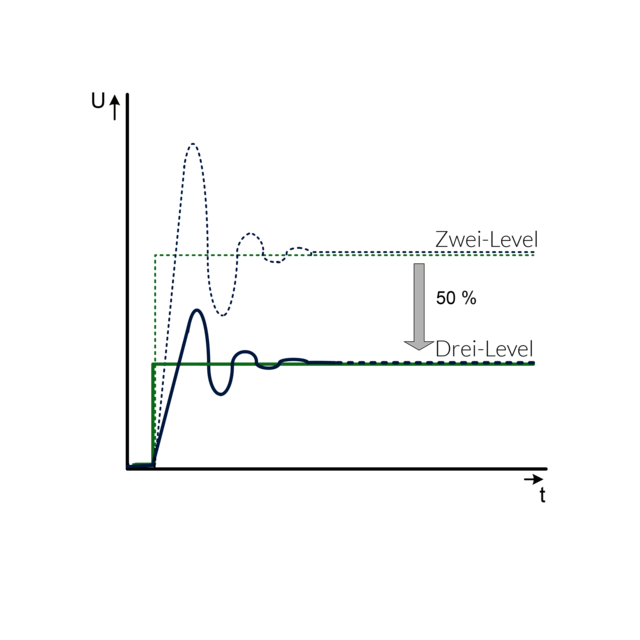

- Very low insulation stress on the motor winding - even with long motor cables - due to 50 % smaller PWM switching amplitudes (see graphic below)

- Optional DC power supply for active magnetic bearings, via internally fused DC link terminals

- Designed for 100 % utilisation 24/7

- All power components designed for 10 years continuous operation at rated load

- Designed for worldwide 3-phase supply networks - also potential-free IT

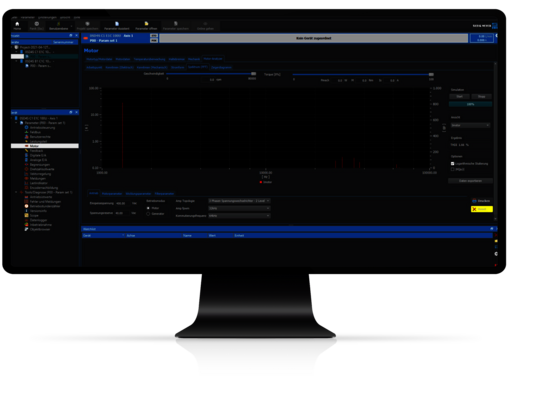

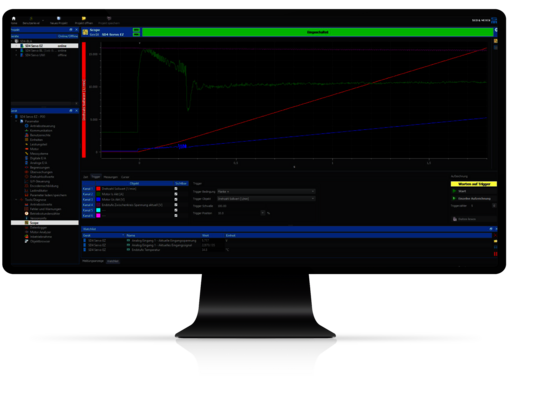

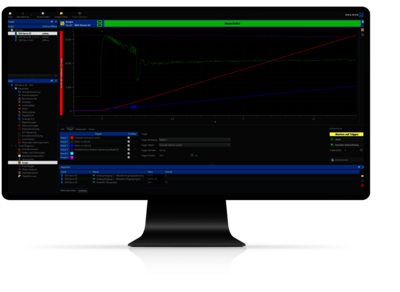

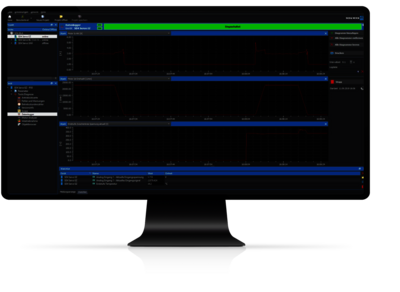

- Powerful parameterisation and diagnostic software drivemaster4

- Customer-specific solutions can be realised

- 3C3 protective coating of the printed circuit boards for operational safety in aggressive environments

The Interfaces of Frequency Converter SD4M

- Mains voltage

- Logic board

- Motor connection

- Liquid cooling

Drive Functions and Safety Functions

Simulation, commissioning, monitoring: drivemaster4

Simulation

- Electrical operating points

- Influence of PWM frequency/inverter topology

- FFT analysis including THDi/THDu calculation

- Export of simulation data

Commissioning

- Parameterisation of the motor data/interfaces

- Optimisation by means of oscilloscope

- Commissioning tool

Monitoring

- Data logger

- Real-time clock

- Error memory

- Operating hours counter

Technical Specifications of Frequency Converter SD4M

with 3-phase AC Mains Voltage without Brake Chopper

Voltage class 400 VAC

Input voltage range 180 .. 528 VAC

| Device type | Mains voltage | Output power (kW) | Output apparent power (kVA) | Output current (A) | Max. output current (A) | HxWxD (mm) | Weight | Cooling |

|---|---|---|---|---|---|---|---|---|

| 0SD4MC1C1Fxxxx | 3 x 400 VAC | 62 kW | 62 kVA@16 kHz | 100 A@16 kHz 3) | 130 | 445 x 260 x 247 | 20 kg | Air |

| 0SD4MD3D1Fxxxx | 3 x 400 VAC | 97 kW | 114 kVA@16 kHz | 165 A@16 kHz | 165 | 685 x 388 x 188 | 30 kg | Water 1) |

| 0SD4MD1D1Fxxxx | 3 x 400 VAC | 72 kW | 83 kVA@16 kHz | 120 A@16 kHz | 165 | 656 x 545 x 218 | 34 kg | Air |

| 0SD4ME3E1Fxxxx | 3 x 400 VAC | 150 kW | 177 kVA@16 kHz | 255 A@16 kHz | 255 | 771 x 439 x 207 | 43 kg | Water 1) |

| 0SD4ME3F1Fxxxx | 3 x 400 VAC | 180 kW | 215 kVA@16 kHz | 310 A@16 kHz | 310 | 771 x 439 x 207 | 43 kg | Water 1) |

| 0SD4ME1F1Fxxxx | 3 x 400 VAC | 115 kW | 132 kVA@16 kHz | 190 A@16 kHz | 255 | 746 x 629 x 273 | 54 kg | Air |

| 0SD4ME1F1Fxxxx | 3 x 400 VAC | 130 kW | 152 kVA@16 kHz | 220 A@16 kHz | 310 | 746 x 629 x 273 | 54 kg | Air |

| 0SD4MG2H1Fxxxx | 3 x 400 VAC | 285 kW | 333 kVA@16 kHz | 480 A@16 kHz | 480 | 1317 x 336 x 489 | 94 kg | Water 2) |

| 0SD4MG2K1Fxxxx | 3 x 400 VAC | 365 kW | 436 kVA@16 kHz | 630 A@16 kHz | 630 | 1317 x 336 x 489 | 94 kg | Water 2) |

| 0SD4MG1H1Fxxxx | 3 x 400 VAC | 205 kW | 236 kVA@16 kHz | 340 A@16 kHz | 480 | 1317 x 684 x 374 | 133 kg | Air |

| 0SD4MG1K1Fxxxx | 3 x 400 VAC | 265 kW | 308 kVA@16 kHz | 445 A@16 kHz | 630 | 1317 x 684 x 374 | 133 kg | Air |

| 0SD4MH3L1Fxxxx | 3 x 400 VAC | 490 kW | 554 kVA@8 kHz | 800 A@8 kHz | 800 | 1478 x 353 x 596 | 136 kg | Water 1) |

1) Cooling pipes aluminum

2) Cooling pipes copper

3) Max. switching frequency 32 kHz

News

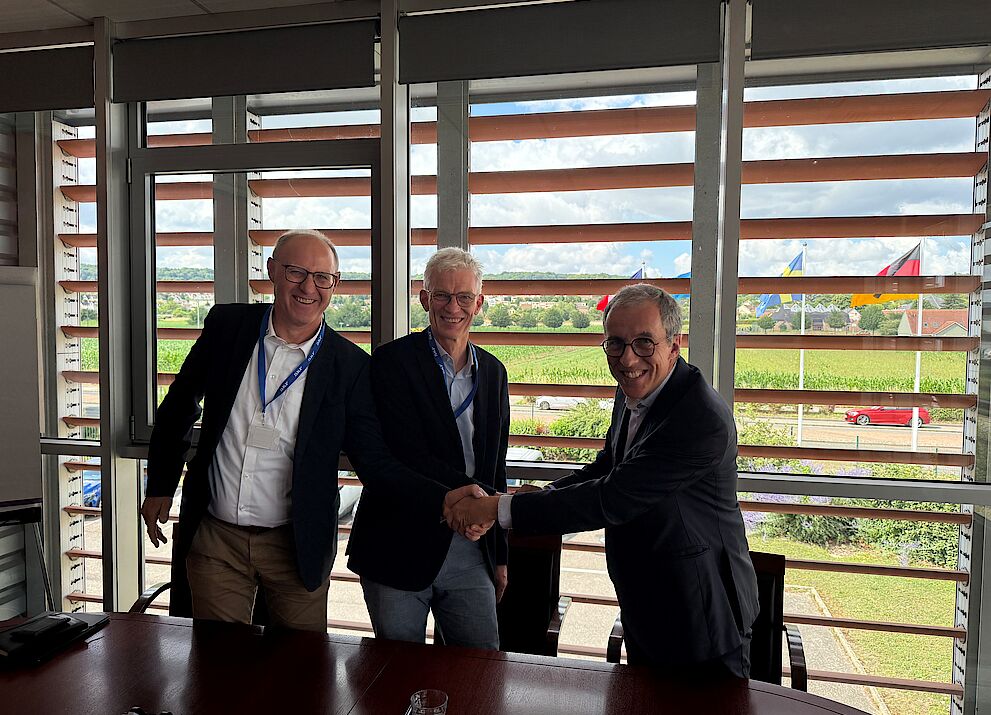

SIEB & MEYER AG Doubles Sales in 2025

SIEB & MEYER AG Presents SD4x Generation with Innovative Features at the SPS Trade Show 2025

SIEB & MEYER AG and SKF announce collaboration

Feel free to contact us

![[Translate to Englisch:] Frequenzumrichter SD4M](/fileadmin/_processed_/6/d/csm_Header_SD2M_Turbo_6c48a45210.png)

Frequency Converter SD4M

Standard converters in the higher power classes typically use the well-known technology of two-level pulse width modulation (PWM) with max. 8 kHz switching frequency. In most high-speed applications, this requires additional components such as LC filters or chokes to minimize the additional losses in the engine. SIEB & MEYER frequency converters of series SD4M are specially designed for high-speed applications and use the innovative three-level technology – also called multi-level technology.

The SD4M devices follow the successful SD2M series and are designed for stationary use in control cabinets of turbo compressors as well as for applications such as ORC, gas expansion and flywheel.

The Top Booster

The three-level technology is of great advantage in these applications because in most cases the SD4M converters do not require motor filter elements. This additional value is achieved by the three-level technology, as well as the PWM switching frequency of up to 16 kHz as standard and optionally up to 32 kHz for dedicated versions. The combination leads to a considerably improved motor current quality, which significantly reduces the undesired rotor losses – by up to 90 %!

| Technology/ System-Property | SD4M Three-level PWM | Standard converter Two-level PWM with motor choke | Standard converter Two-level PWM with LC filter |

|---|---|---|---|

| Low weight | ✓ | X | X |

| Small installation space | ✓ | X | X |

| No risk of resonance effects | ✓ | ✓ | X |

| Total costs | ✓ | X | X |

Highlights

Three-Level Technology

- Function: The output stages of SD4M Turbo are based on a three-level technology and provide rotating field frequencies up to 2,000 Hz with switching frequencies of 16 kHz.

- Advantage: Reduced motor losses combined with minimum efforts for motor filters and motor chokes as well as low interfering radiation and insulation stress.

- Benefit: Low system costs over the whole product life cycle.

Efficiency

- Function: The devices reach efficiencies of up to 98 %.

- Advantage: The high efficiency of the devices ensures optimal system efficiencies and reduces cooling requirements.

- Benefit: Maximum system output and lower environmental footprint due to lower energy consumption.

DC Supply

- Function: Active emergency braking and maintenance of voltage supply in case of power supply failure.

- Advantage: No separate voltage supply for the magnetic bearings needed.

- Benefit: Protection of the magnetic bearings in case of power failure as well as cost savings.

Our Experience in High-speed Technology - Your Advantage!

Up to 60 % reduced installation space for the required electrical components

Improved availability due to the reduced number of components

Up to 50 % reduced weight for the required electrical component

Reduced environmental footprint due to lower energy consumption

Significantly less wiring- and assembly work

Connectivity for the future Ethernet/web server/EtherCAT/Modbus

Cost reduction for IPM the drive chain

Maximum performance of IPM motors through dynamic operating point control

Improved efficiency of the overall system

Motor Currents by Comparison

Good to Know

- Currently available power classes from 100 to 500 kVA, with up to 800 Aeff rated current.

- Liquid cooling as standard (water-based), air cooling on request

- NRTL/CSA certified

- Very low insulation stress on the motor winding - even with long motor cables - due to 50 % smaller PWM switching amplitudes (see graphic below)

- Optional DC power supply for active magnetic bearings, via internally fused DC link terminals

- Designed for 100 % utilisation 24/7

- All power components designed for 10 years continuous operation at rated load

- Designed for worldwide 3-phase supply networks - also potential-free IT

- Powerful parameterisation and diagnostic software drivemaster4

- Customer-specific solutions can be realised

- 3C3 protective coating of the printed circuit boards for operational safety in aggressive environments

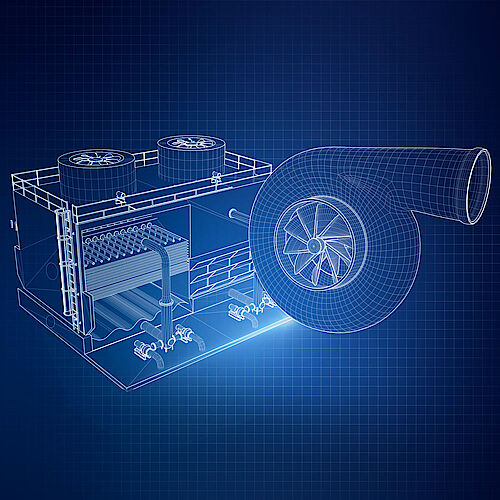

The Interfaces of Frequency Converter SD2M for Turbo Applications

![[Translate to Englisch:] Frequenzumrichter SD4M](/fileadmin/_processed_/f/c/csm_2500x2500_Schnittstellen_a09165ac37.png)

- Mains voltage

- Logic board

- Motor connection

- Liquid cooling

Drive Functions and Safety Functions

Simulation, commissioning, monitoring: drivemaster4

Simulation

• Electrical operating points

• Influence of PWM frequency/inverter topology

• FFT analysis including THDi/THDu calculation

• Export of simulation data

Commissioning

• Parameterisation of the motor data/interfaces

• Optimisation by means of oscilloscope

• Commissioning tool

Monitoring

• Data logger

• Real-time clock

• Error memory

• Operating hours counter

Technical Specifications of Frequency Converter SD4M

with 3-phase AC Mains Voltage without Brake Chopper

Voltage class 400 VAC

Input voltage range 180 .. 528 VAC

| Device type | Mains voltage | Output power (kW) | Output apparent power (kVA) | Output current (A) | Max. output current (A) | HxWxD (mm) | Weight | Cooling |

|---|---|---|---|---|---|---|---|---|

| 0SD4MC1C1Fxxxx | 3 x 400 VAC | 62 kW | 62 kVA@16 kHz | 100 A@16 kHz 3) | 130 | 445 x 260 x 247 | 20 kg | Air |

| 0SD4MD3D1Fxxxx | 3 x 400 VAC | 97 kW | 114 kVA@16 kHz | 165 A@16 kHz | 165 | 685 x 388 x 188 | 30 kg | Water 1) |

| 0SD4MD1D1Fxxxx | 3 x 400 VAC | 72 kW | 83 kVA@16 kHz | 120 A@16 kHz | 165 | 656 x 545 x 218 | 34 kg | Air |

| 0SD4ME3E1Fxxxx | 3 x 400 VAC | 150 kW | 177 kVA@16 kHz | 255 A@16 kHz | 255 | 771 x 439 x 207 | 43 kg | Water 1) |

| 0SD4ME3F1Fxxxx | 3 x 400 VAC | 180 kW | 215 kVA@16 kHz | 310 A@16 kHz | 310 | 771 x 439 x 207 | 43 kg | Water 1) |

| 0SD4ME1F1Fxxxx | 3 x 400 VAC | 115 kW | 132 kVA@16 kHz | 190 A@16 kHz | 255 | 746 x 629 x 273 | 54 kg | Air |

| 0SD4ME1F1Fxxxx | 3 x 400 VAC | 130 kW | 152 kVA@16 kHz | 220 A@16 kHz | 310 | 746 x 629 x 273 | 54 kg | Air |

| 0SD4MG2H1Fxxxx | 3 x 400 VAC | 285 kW | 333 kVA@16 kHz | 480 A@16 kHz | 480 | 1317 x 336 x 489 | 94 kg | Water 2) |

| 0SD4MG2K1Fxxxx | 3 x 400 VAC | 365 kW | 436 kVA@16 kHz | 630 A@16 kHz | 630 | 1317 x 336 x 489 | 94 kg | Water 2) |

| 0SD4MG1H1Fxxxx | 3 x 400 VAC | 205 kW | 236 kVA@16 kHz | 340 A@16 kHz | 480 | 1317 x 684 x 374 | 133 kg | Air |

| 0SD4MG1K1Fxxxx | 3 x 400 VAC | 265 kW | 308 kVA@16 kHz | 445 A@16 kHz | 630 | 1317 x 684 x 374 | 133 kg | Air |

| 0SD4MH3L1Fxxxx | 3 x 400 VAC | 490 kW | 554 kVA@8 kHz | 800 A@8 kHz | 800 | 1478 x 353 x 596 | 136 kg | Water 1) |

1) Cooling pipes aluminum

2) Cooling pipes copper

3) Max. switching frequency 32 kHz

Applications

About Sieb & Meyer

SIEB & MEYER AG - Drive and control solutions of the latest generation

SIEB & MEYER was founded in 1962 and is a successful company in the field of industrial electronics. With around 300 employees worldwide today, we develop and manufacture control technology and drive electronics. Our core technologies include controllers for mechanical engineering and automation technology, servo amplifiers for a wide range of drives and frequency converters for high-speed motors and generators.

Contact

SIEB & MEYER AG

Auf dem Schmaarkamp 21

D-21339 Lüneburg

Phone: +49 4131 203 0

Fax: +49 4131-203 2000

You can find all sales contacts at: www.sieb-meyer.com/contact/sales

You can find all agencies and partners at: www.sieb-meyer.com/contact/offices-and-sales-partners