The optimal products for your grinding application

Grinding applications have a special position in the field of machine tools. Internal grinding applications, for example, require sensorless operation of asynchronous and synchronous spindles up to 250,000 rpm.

The motor heating, however, must be kept very low to avoid damaging the sensitive materials and to ensure high machining quality. Another important factor is the flexibility of the machine: Simple and quick exchange of the grinding spindles is essential. For this purpose, the frequency converter should allow storing several motor parameter sets.

In addition, customers often demand special functions like a high-dynamic active load detection. Frequency converters by SIEB & MEYER can fulfill all these requirements and more.

Product Overview

| Device series | Power range | Input voltage | Technology | Speed (frequency) | Type | Communication | Safety functions |

|---|---|---|---|---|---|---|---|

| SD2 | 1 .. 80 kVA | 230 .. 480 VAC | 2 Level PWM | 120,000 1/min (2,000 Hz) | Multi-axis system with central power supply unit | RS485, via Gateway: Profibus, Profinet, EtherCAT | STO, SLOF, SFM |

| SD2S | 0.3 .. 55 kVA | 115 .. 480 VAC | 2 Level PWM | 120,000 1/min (2,000 Hz) | Single-axis device | RS232, CAN Bus, EtherCAT, via Gateway: Profibus, Profinet | STO |

| SD2S-FPAM | 1.5 .. 3.8 kVA | 115 .. 230 VAC | Regulated intermediate circuit (PAM, FPAM) | 480,000 1/min (8,000 Hz) | Single-axis device | RS232, CAN Bus, EtherCAT, via Gateway: Profibus, Profinet | STO |

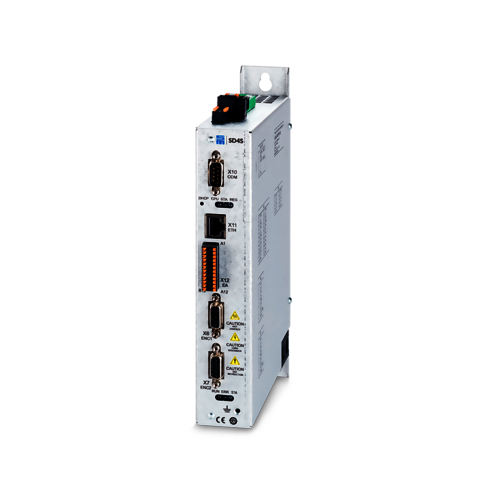

| SD4S | 0.8 .. 66 kVA | 115 .. 230 VAC | 2 Level PWM | 240,000 1/min (4,000 Hz) | Singl-axis device | CANopen, EtherCAT, (Profinet, Powerlink) | STO |

Control systems & drive technology – customized for your application

With our experience from customized drive systems that are meanwhile produced in large series and as well as our standard devices, we are supporting you from the project planning phase to the series production.