Highest Precision for Depth-Controlled Processing of PCBs

Technical papers

SIEB & MEYER provides smart SLM software for drilling and routing machines

During PCB production especially depth-controlled processes require an intelligent and intuitive control. Additionally to its well-proven CNC controls SIEB & MEYER implemented the optional software package SLM (Smart Layer Manager) which can meet the increasing requirements of the market regarding quality and precision of processing machines. Ernst Lenz Maschinenbau GmbH already successfully uses the smart tool.

In the PCB manufacturing the trend of a steadily increasing functional integration density of assemblies continues. Increasing signal speeds require an accurate PCB design and a high manufacturing quality. An even higher process precision is especially required for depth-controlled drilling and routing, while the number of quality-decisive parameters increases. Additionally, corresponding manufacturing data must be collected and stored for analysis and quality control. To meet these requirements SIEB & MEYER AG has developed an optional software package SLM for the CNC 84.00 control generation. Firstly, the purpose was to meet the increasing requirements of the market regarding depth-controlled drilling and routing, for processes such as back drilling or routing residual webs. Secondly, the purpose was an innovative realization to inspire the users even in the coming years. Thirdly, an increasingly important aspect is usability: "Despite the complex functionality the operator shall be able to easily and traceably configure the required process parameters," explains Holger Dornau, Head of Sales and Marketing for CNC at the SIEB & MEYER AG.

Software package enables new possibilities

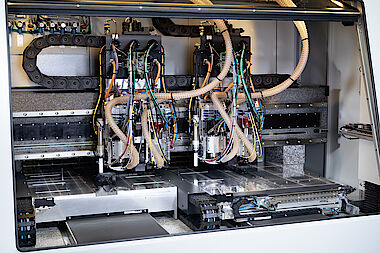

The company Ernst Lenz Maschinenbau GmbH has already decided to use the innovative software package. "We've been manufacturing PCB drilling and routing machines since 1968," says Uwe Lenz, Managing Director. "Our focus is on special applications and niche solutions." Depth-controlled PCB processing has been a standard for a long time, but the requirements towards precision get constantly higher. Hence, Lenz developed the drilling and routing machine series DRB 610-1+1 with the following functions: The board is positioned in the XY-direction by means of a CCD camera and measured with different depth measurement sensors in the Z-direction. "We use the CNC 84.00 by SIEB & MEYER which already guarantees a high level of precision, productivity and availability," Uwe Lenz explains. "Furthermore, the SLM software makes it possible for us to detect, calculate and consider the measured board tolerances during the working process in real time."

The SLM tool allows for a high-precision PCB processing by means of different powerful techniques which consider the PCB's top side or bottom side or even the top of the backup material as reference plane. The percentage mode makes it possible to additionally consider thickness deviations within the board. "Back drilling is a typical application for depth-controlled processing of PCBs," Holger Dornau explains. "This process is used for manufacturing very expensive boards for the IT industry. Furthermore, it can also be used for depth-controlled routing of very precise embedded structures on the boards which are used in the automotive industry."

Compensate thickness tolerances

"Our drilling and routing machines of the series DRB 610-1+1 are used for processing thick PCBs with 20 or more layers, especially required in the IT industry," Uwe Lenz confirms. "They are, for example, used as backpanels for internet switches." The back drilling process removes through-hole platings within holes to a certain layer in order to avoid interferences at high frequencies. Since the used PCBs are very thick and pressed several times, the thickness tolerance is very high and must be measured and compensated. The tool by SIEB & MEYER helps with this.

The software package SLM is also optimally suited for routing cavities. The background: Embedded components which are placed in the inner layers of the board are increasingly used in the electronics industry. Manufacturers are required to place a very precise and even surface with very small tolerances within the board. "Such multilayer boards are also pressed several times and the thickness tolerances must be compensated," Uwe Lenz says. "The required tolerances are in the micrometer area. This is a challenge that can easily be met with the software provided by SIEB & MEYER.“

Intuitive configuration and use

The configuration process can be easily managed: "The CNC software provides specially coordinated and easy to understand input pages for the configuration," Holger Dornau explains. Parameters such as the thickness of the entry material or a fixed depth offset guarantee the CNC's process precision. The operator can save the set parameters in a configuration file and re-use them later. Detected surface data can also be saved and re-used. "The SLM package enables us to meet our customers different requirements and to embed individual adjustments in the program beforehand." Uwe Lenz emphasizes. "The operator can define all product-related processing steps ahead of time and only needs to load the customized program afterwards."

During the operation the operator is safely guided through the production process by the CNC software. Thus, operating errors can be reduced significantly. The detected planes are displayed in a table in the software. After the measurement and production are finished the data is written into a file. This data is analyzed and used to indicate the achieved production quality. Furthermore, the operator can choose to display the surfaces in the program graphic. The hue and saturation in the graphic provide him with an idea of how even the detected surface is.

Exploit potential and meet challenges

"We reached our initial goal," Holger Dornau concludes. "We implemented a future-oriented software package which exceeds the current requirements." There is still potential for further growth! This is important for customers like Lenz who have to deal with very different and difficult use cases everyday. All of the use cases, without exception, can be solved by means of the software package. Even though there won't be a customer who will need all functions at once, Lenz can use the complete range of the software package and provide every customer and even the ones with unusual application fields with an appropriate solution. "The SLM tool makes it possible to clearly distinguish ourselves from the competition," concludes Uwe Lenz. "It is a perfect addition to the CNC control by SIEB & MEYER, because everything is structured logically."