Press releases

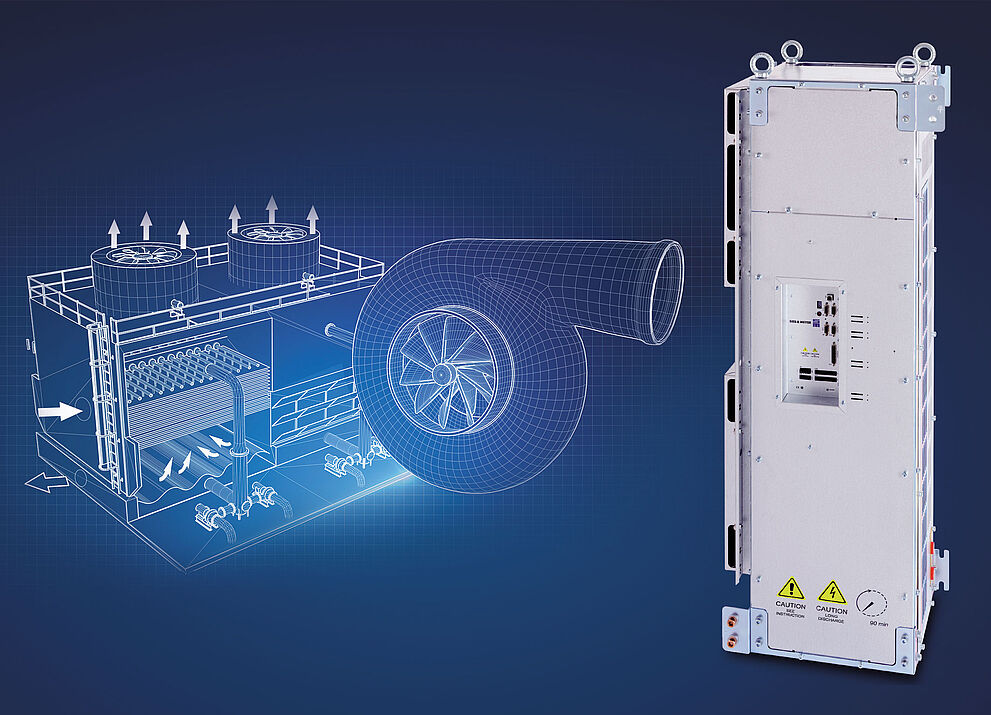

Cool Climate, Cool Technology

Press releases

Frequency Converters – Drivers of the Energy Transition

Press releases

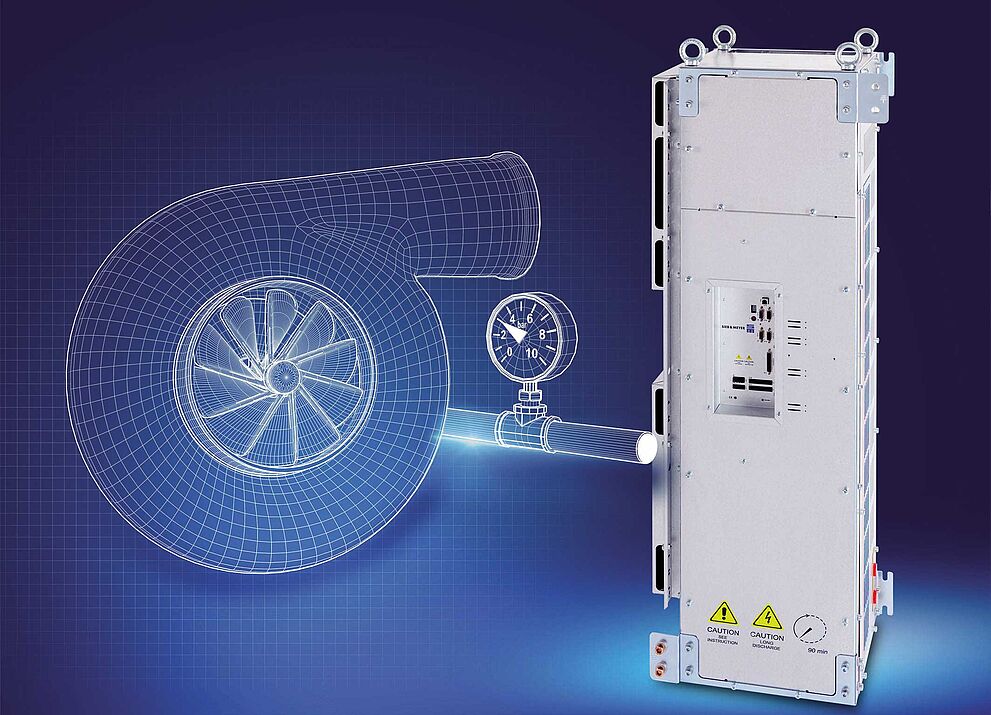

Three-level Technology for Minimal Losses and Increased Efficiency

Press releases

A Compact Multitalent

Press releases

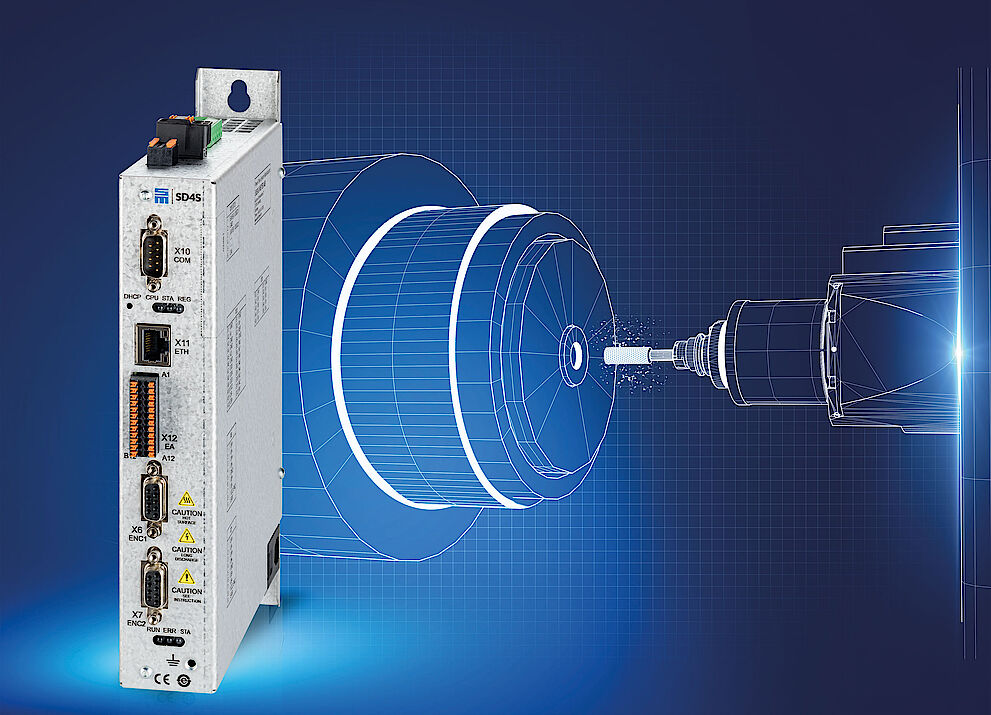

The Stand-alone Variant for High-speed Applications

Press releases

Drive System SD2 by SIEB & MEYER with Integrated Safety Functions

DO YOU NEED MORE INFORMATION?

If you have any further questions, please do not hesitate to contact our press department:

Ms. Annika Ritari

PR, Media and Exhibitions

Phone +49-(0)4131-203 - 1381

E-Mail Annika.Ritari@sieb-meyer.de