CNC News

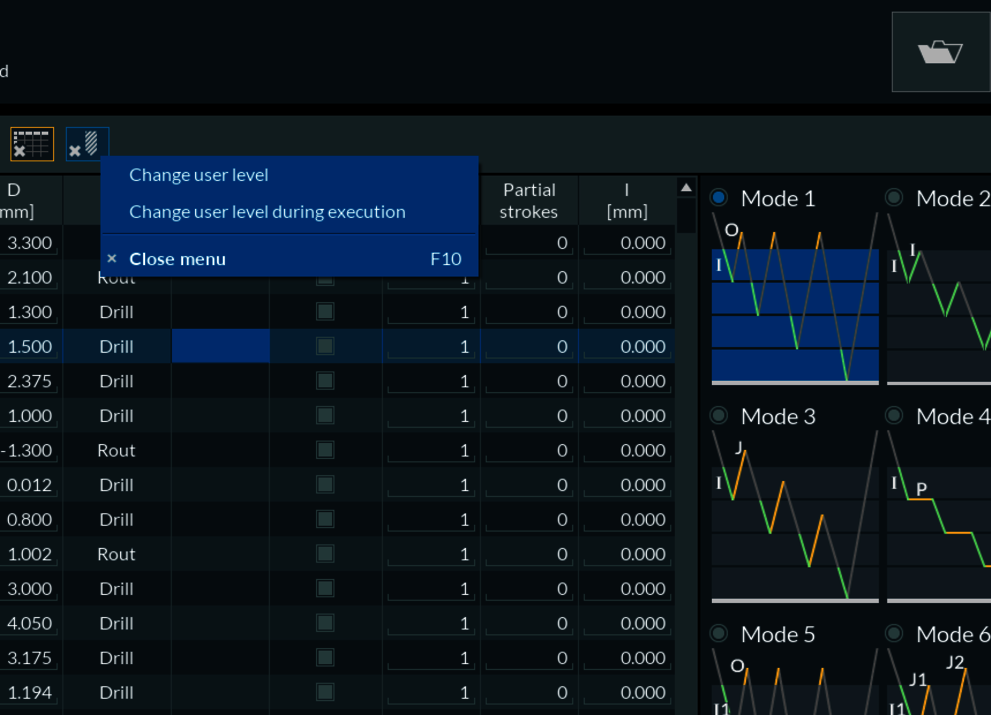

Control Clear Functions Easily with User Level

CNC News

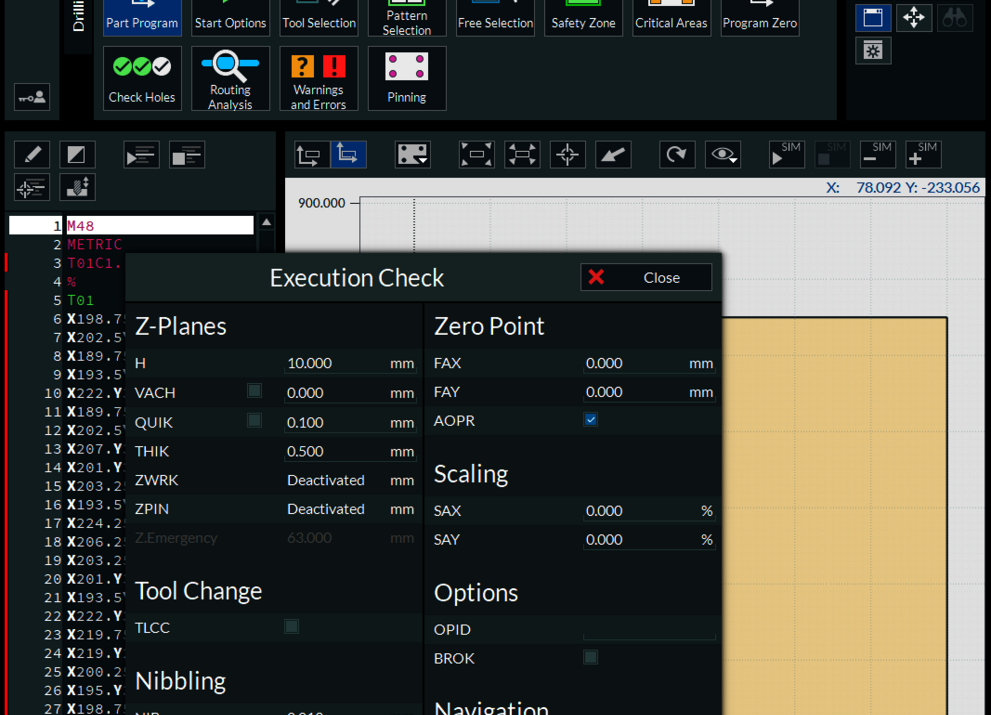

More Efficient Operation Thanks to Customized User Interface

CNC News

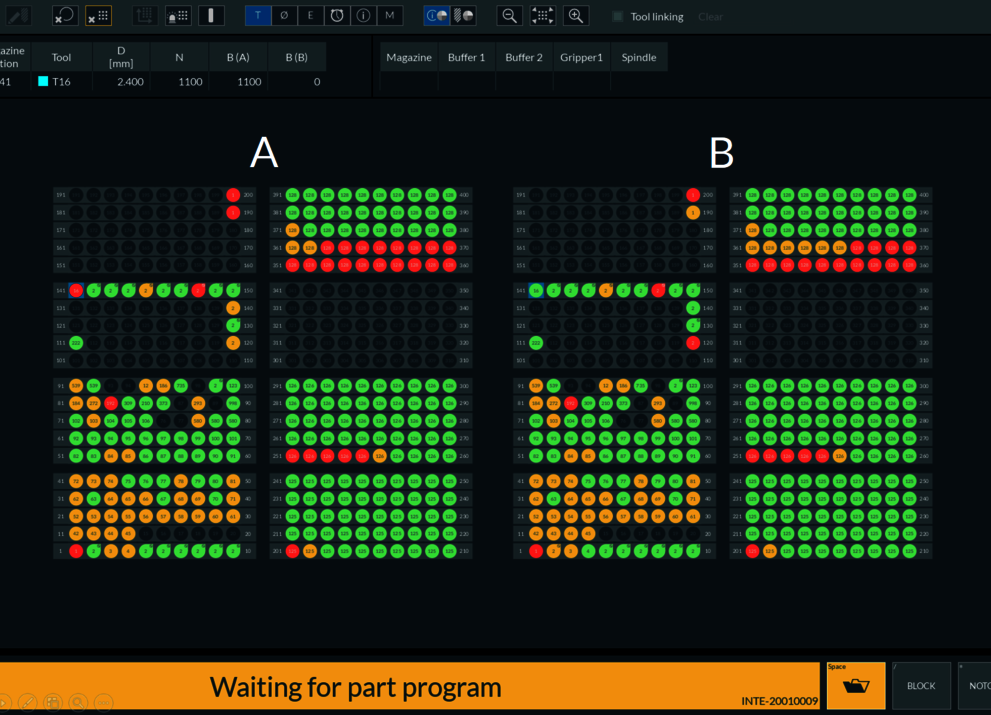

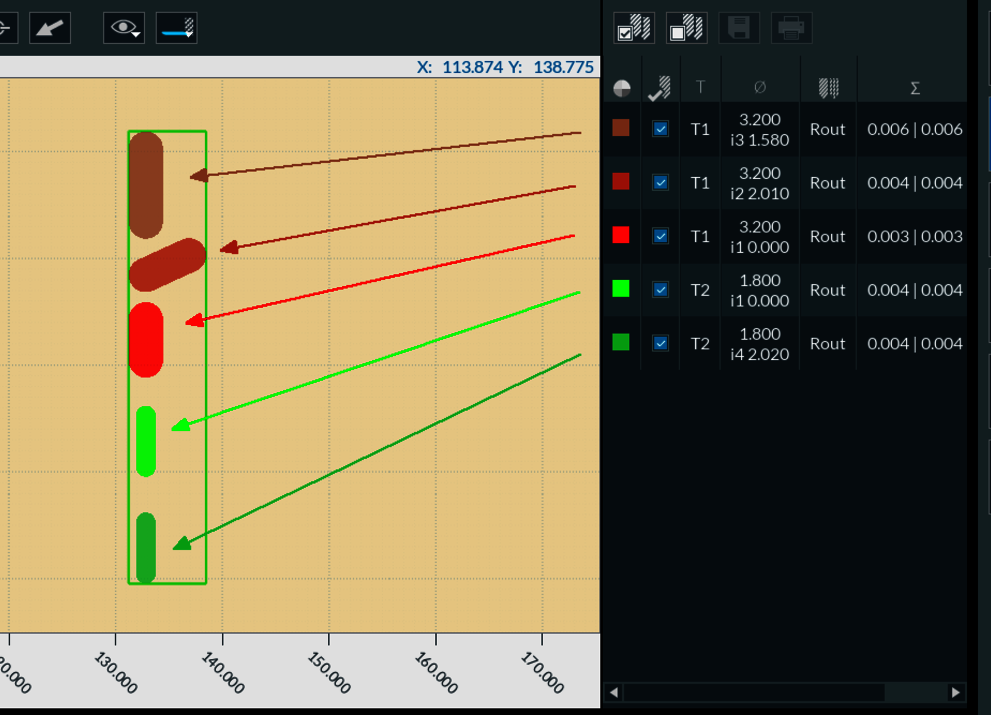

Save Costs with Customized Tool Life

CNC News

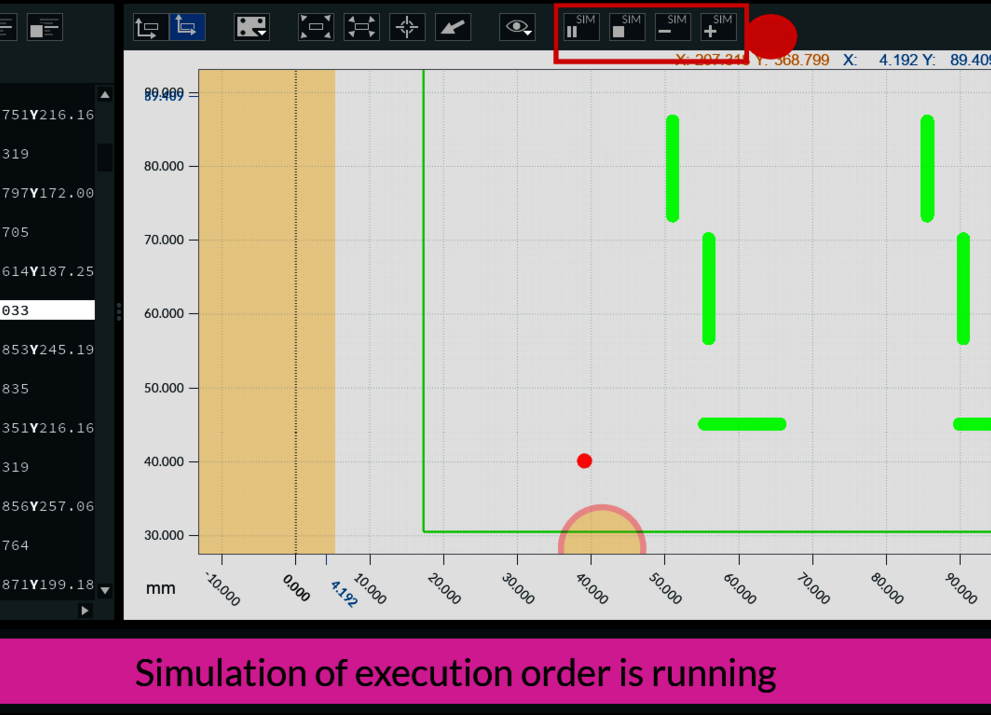

Program simulation promotes error-free production

CNC News

Experience the next level of routing applications!

CNC News