Save Costs with Customized Tool Life

CNC NewsExpensive tools can be used more efficiently. With the pod-individual tool life management function, the SIEB & MEYER CNC 9x.00 offers the option of utilizing the tool life for tools individually and to the maximum extent possible. This saves costs for tools.

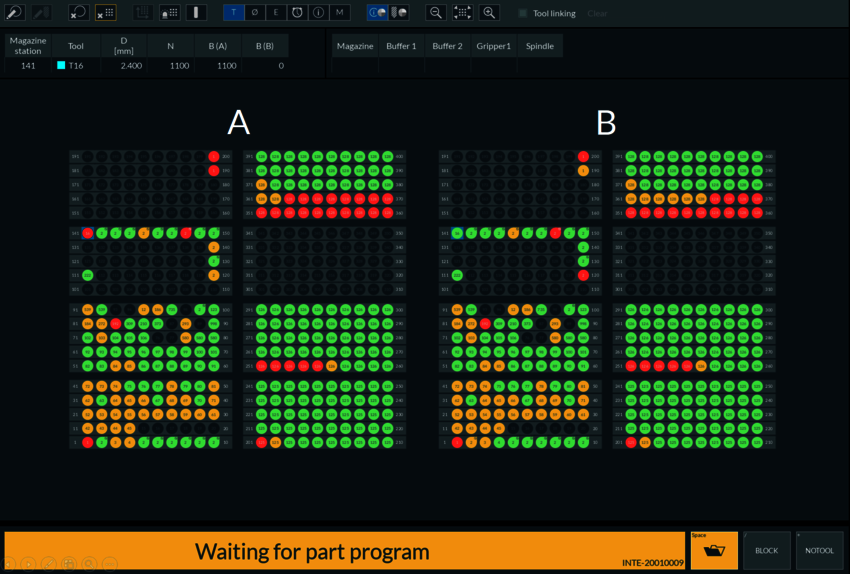

Tools can now be replaced individually for each pod with the pod-individual tool life management function. The CNC command AITL allows several different tool lives per tool number for MWS machines. For example, the “used” status can be applied several times for a tool number in order to lock and release the tool of a pod again after a few runs. The magazine view clearly displays the actual tool lives per pod and tool.

Special advantages arise regarding the tool number conversion: The tools of magazine A and B must not be replaced in general while changing the part program. For example, tool T1 from A can continue to be used because the tool life has not yet been reached, but the tool from B can be replaced. The risk of using broken tools for production is minimized at the same time.

The CNC control system CNC 9x.00 also offers a script function for this, which evaluates and resets the service life in a differentiated way. SIEB & MEYER's SM IIoT Connect provides interfaces to Automated Guided Vehicles and in-house process analysis tools, which support the process-oriented management of tools and offer greater planning reliability. Overall, the new function for pod-individual tool life management provides several advantages: Tool lives can be customized, tools are used optimally, utilized to the maximum and material costs are saved.