Screw Tightening with Straightforward Control

Technical papers

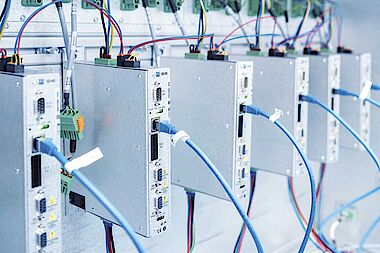

Recently developed servo amplifier proves successful in screwdriving control

For six decades, WEBER has been setting standards in the development and production of automatic handheld screwdrivers and stationary tightening systems – and for more than 20 years, the company has been cooperating with SIEB & MEYER. Now, the two companies are breaking new ground together: the new servo amplifier SD4S is used in the process control C5S ensuring high dynamics, good synchronization and precise cutoff.

The product variant SD4S – S for stand-alone – marked the beginning of the new SD4x series by SIEB & MEYER. This device family is suited to stationary applications in switch cabinets, e.g. for machine tools or turbo blowers/compressors, and succeeds the well-proven device series SD2S, which is also in use at WEBER. The close collaboration with WEBER proved a stroke of luck for the product development: "We were in close contact with WEBER already in the early development stages of the SD4S series," related Ralph Sawallisch, key account manager drive technology at SIEB & MEYER. Beforehand, the specialist for screw tightening systems had already signaled his interest in testing and, if proven successful, using the new device. "We received a lot of important input from WEBER, which we have implemented. When the first prototypes were available, WEBER was the first customer to put the device through its paces."

Screw tightening technology for the automation industry

WEBER Schraubautomaten GmbH based in Wolfratshausen, Germany, is a trendsetter in automation engineering regarding handheld and stationary screw tightening technology including feeding systems. The product range comprises electric handheld screwdrivers, spindles for tightening technology, stationary screwdriving systems, tightening units and tightening systems – each adapted to the specific customer requirements. All these devices are designed to make the tightening process as fast and as reliable as possible. "Automation processes for assembly work are very complex," said Christian Schönig, head of development at WEBER. "It is about finding solutions that meet various requirements and parameters." The servo amplifiers by SIEB & MEYER help with this aim – for several decades now.

Indirect control of simple tightening tasks

When SIEB & MEYER started the development of the new SD4x series, the collaboration of the two companies reached a new phase. "Our main requirements for SD4S were a smaller size and a reduced price compared to SD2S," remembered Christian Schönig. "These were prerequisites for the use of the device in our process control C5S." This screwdriving control can perform various screw tightening tasks using different screwdriving methods, which take the torque, angle and depth into account. The C5S control comes with a wear-free servo drive that ensures an extended service life of the control and the drive unit

C5S is the ideal control for tightening tasks that do not require highly precise torque measurement or documentation of the tightening results. The control is used, for example, in furniture production to fasten fittings and hinges. When tightening screws in wood, the torque fluctuates due to the varying texture of the natural material. Therefore, direct measurement of the torque is not necessary, which makes an indirect torque determination by the servo amplifier possible.

Flexibility for various applications

In the C5S control, WEBER uses the smallest SD4S model so far with an AC mains supply of 230 V – even smaller devices require a DC voltage between 48 and 72 V. The SD4S drives the motor of the tightening spindle that tightens the screw via the bit. During this process, the servo amplifier uses the measured motor current to determine the torque at the screw. The torque should be as precise as possible over the rotation angle of the motor. Hereby, SD4S effectively reduces motor cogging. The cogging torque of synchronous servo motors is created by the permanent magnets in the rotor. Depending on the motor design, the effect varies in intensity. The high-dynamic control of SD4x reduces that effect to a minimum so that the resulting torque at the screw is remarkably uniform

Another important feature for WEBER is the simple and low-cost connection of the controller via CANopen. "Other fieldbus systems cause further costs on both sides of the bus," explained Christian Schönig. "Equally important is the fact that SD4S allows controlling servo motors of various manufacturers." With the multi parameter set function, users can connect different motors to the servo amplifier without further parameterization effort. The integrated EMC filter reduces the costs for an external filter circuit.

Individual adaptations of the series device

"For this project, a special motor is used because it comes with a manufacturer-specific rotor position encoder," said Ralph Sawallisch. "We adapted our SD4S device for WEBER so that it can reliably evaluate this encoder." Christian Schönig adds some background information: "There are small-build motors on the world market but they have manufacturer-specific feedback systems. SD4S can evaluate these, which means more flexibility in the motor selection for us. In light of the current supply problems, this opens up alternatives regarding the motors we use.

Christian Schönig considers exactly that as the unique selling point of SIEB & MEYER: product flexibility without compromises in terms of price and support. But the head of development also appreciates the technically sound communication: "SIEB & MEYER knows the customer and the special use case. The communication is at eye level and we get honest answers." Not surprisingly, WEBER analyzes whether SD4S is also suitable for other products – the additional fieldbus systems, in the meantime implemented by SIEB & MEYER, make other applications possible.