Quality Assurance with Contour Cleaning in the CNC 93.00

CNC NewsThe routing control CNC 93.00 sets new standards to achieve the highest possible dimensional accuracy and quality. To meet the high requirements for routing machines, SIEB & MEYER enhanced its CNC 93.00 with the "contour cleaning" function. With this function the milled part is not only freed from dust and chip, but also finished to guarantee a high-quality routing result.

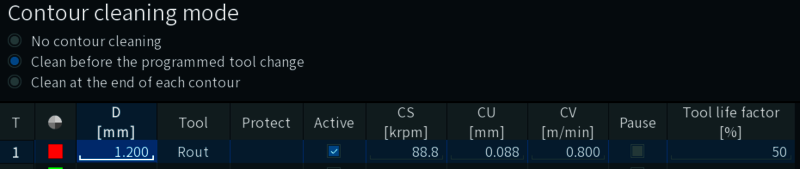

Thanks to the tool page "Contour Cleaning" in the user interface, the CNC 93.00 enables selection and definition of tools and corresponding tool parameters for contour cleaning. There are two different modes available:

- The contour is cleaned before the tool change programmed in the part program (s. setting "Clean before the programmed tool change" in figure 1)

- The contour is cleaned at the end of each routing contour in the part program (s. setting "Clean at the end of each contour" in figure 1)

In both modes the following cleaning parameters can be defined for the cleaning tool: spindle speed (CS), compensation diameter (CU), routing feed rate (CV) and a factor for calculating the tool life (s. "Tool life factor"). Especially the parameter "Tool life factor" makes it possible to save tools, as the lower tool wear during the cleaning process is taken into consideration for the tool life.

A pause function is available for contour cleaning before the programmed tool change: By means of a "pause" the operator can stop the execution automatically in order to e.g. manually remove dust or chip or to check the dimensional accuracy of the milled part. Additionally, scripting enables customized adjustments of the cleaning process.

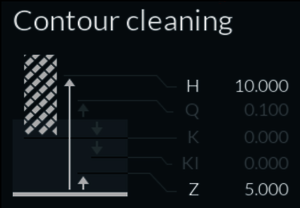

If contour cleaning is performed, it is displayed on the Dashboard of the CNC 93.00 during the time of execution (s. figure 2).

The customer benefits from the enhancement of the routing control CNC 93.00 in terms of quality assurance. Furthermore, the tool page "Contour Cleaning" in the user interface provides a customer-friendly and simple solution to define cleaning parameters used for this process.