Critical Areas - a Feature in CNC 95.00

CNC NewsCritical Areas are a special new feature in CNC 95.00. Their main objective is to ensure a fast and safe production.

Definition

Critical Areas can be defined within the working area and/or within the Safety Zone. These areas are referred to as "critical" because the Z-axis cannnot move as close to the work piece as in the Safety Zone: In the Safety Zone the Z-axis can be moved on the H- or Quick-plane; whereas in the Critical Area it can be moved on the SZH- or SZQ-plane. The traveling plane of a Critical Area must be defined higher, so the Z-axis won't collide with the installed clamping systems or pins.

Background

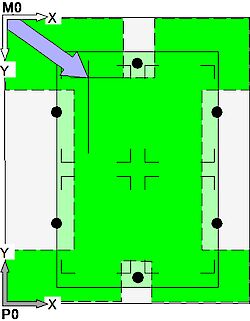

The approach for Critical Areas already existed in the CNC 8x.00. However, these areas could only be configured by expanding the Safety Zone.

The Safety Zone (green) was expanded and the cutouts (light green) correspond to Critical Areas. The setting of such areas was not flexible and has been picked up and optimized in CNC 95.00.

Setting

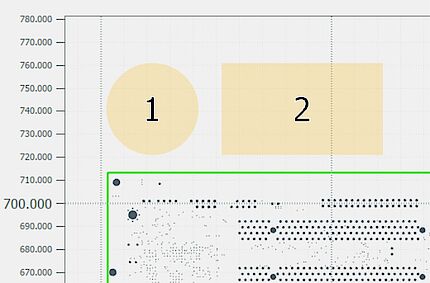

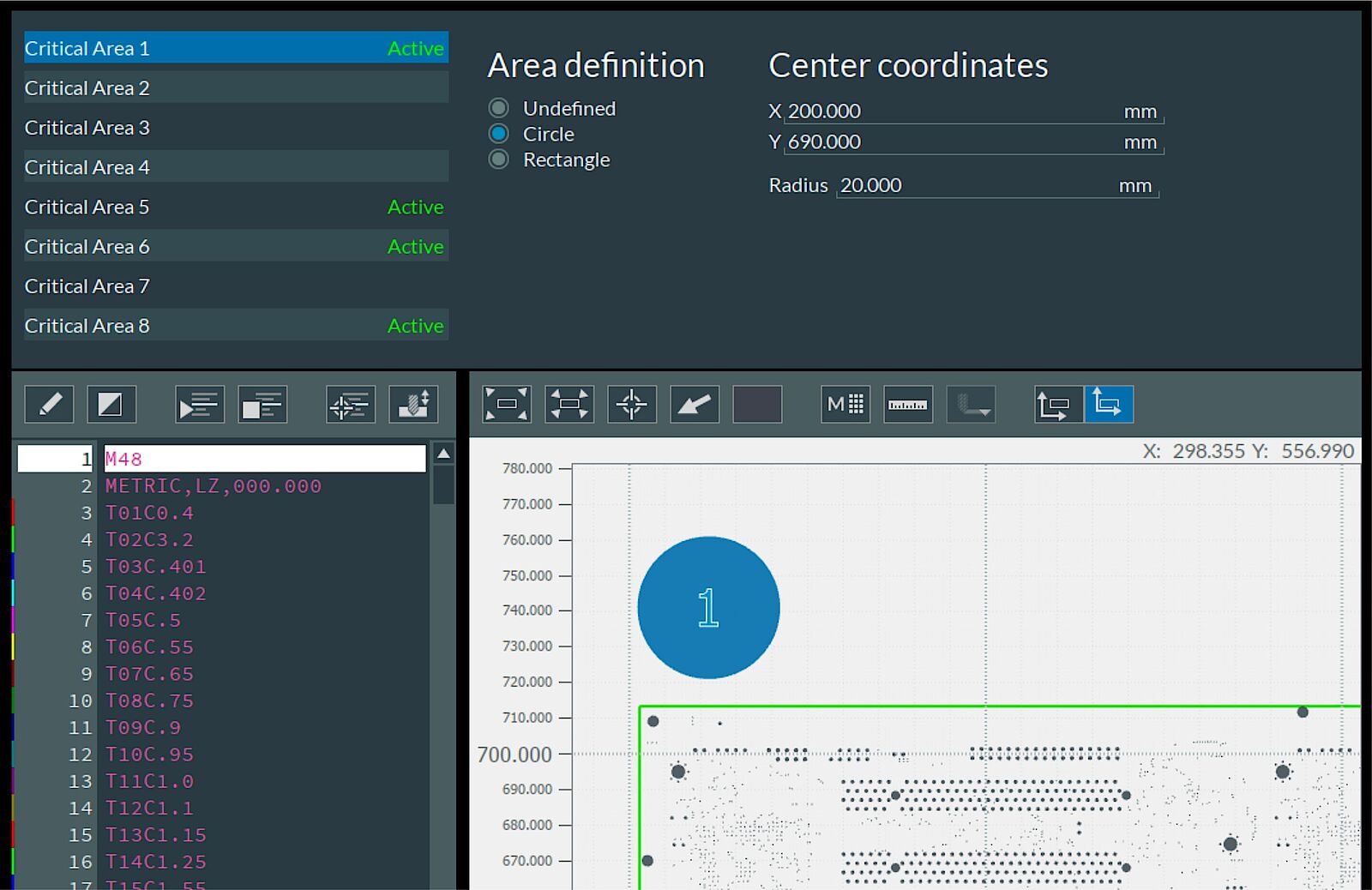

The implemented solution in CNC 95.00 allows for a definition of up to 8 Critical Areas within the working area and/or the Safety Zone. It is also possible to choose a form for the Critical Area in accordance with customer requirements: circular or rectangular.

The user can easily define Critical Areas in the graphic view or in the page "Critical Areas" where he can also manage them.

Thanks to this feature it is possible to define specific areas to ensure safety of the machine and the work piece without unnecessarily slowing down the execution.