Individual Control of Processes via Events in the CNC 9x.00

CNC NewsThe SIEB & MEYER CNC 9x.00 makes is possible to control processes during execution via events. Thus, external hardware for continuous broken tool monitoring can be integrated into the process. When an event occurs, the linked script is started and an especially programmed machine process is executed.

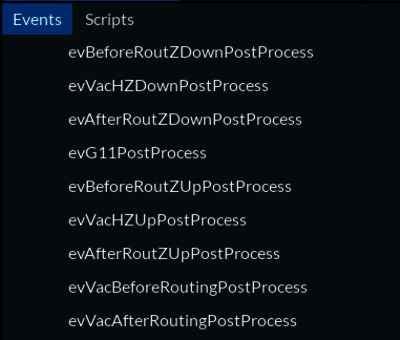

See the following possible events in the "Scriptor" which trigger postprocesses:

In the Configurator additional settings, such as individual stops, can be configured under "Event control". It is possible to define stops before the start and/or after the end of routing. If a setting is activated, the process during routing is stopped for the duration in which the linked customer-defined postprocess script is executed.

Examples

- Continuous broken tool monitoring via external hardware

The event "evAfterRoutZDownPostProcess" triggers a stop after the Z-axis has been lowered (Stop after Z down) and starts the linked postprocess script immediately before the start of routing. Thus, external hardware for continuous broken tool monitoring can be activated. - Switch pressure foot

The event "evBeforeRoutZDownPostProcess" triggers a stop before the lowering of the Z-axis (Stop before Z down), i.e. before the Z-axis is lowered for routing. Thus, the pressure foot can be switched accordingly.

Thanks to the postprocess events it is also possible to enhance the G11 finish-routing function individually.

The Configurator settings for event control provide a further possibility to flexibly adjust the production process. Thus, the machine manufacturer is always able to react to new requirements.