Program Zero

CNC NewsA Feature in CNC 95.00 and CNC 93.00

For simplifying the work setup at the machine, the CNC software provides the page "Program Zero" with different comfortable functions. Thanks to the supporting functions the operator is able to finish his work quicker and more secure, whilst reducing errors and costs.

Page "Program Zero"

The page "Program Zero" serves to determine a suitable position for the board stacks on the work stations. The page provides different functions in the corresponding tabs for determining the suitable offset.

Align with Fixed Pin Positions

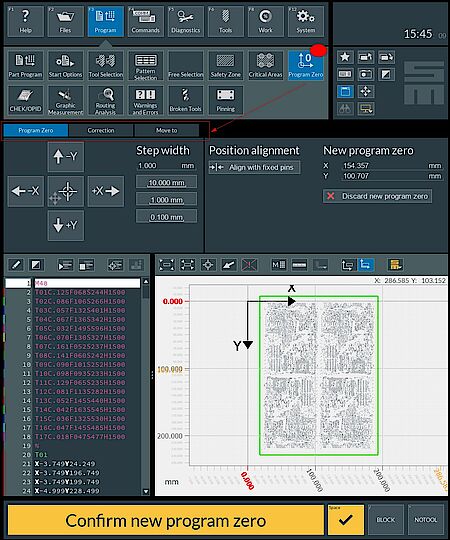

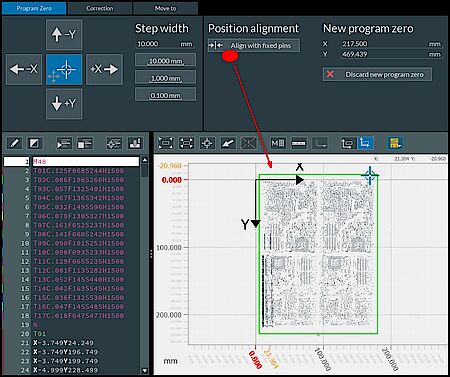

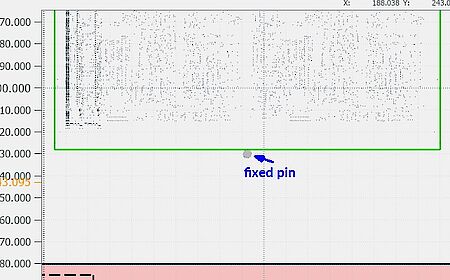

After loading a part program, you can use the function "Align with fixed pins" to determine the work offset if a fixed pin position, e.g. a pin/prism, is defined in the Configurator. The function shifts the program centered over the fixed pin position (s. 2nd figure). If no fixed pin position is defined, the program will be shifted to the middle of the working area.

Shift Manually with XY-buttons

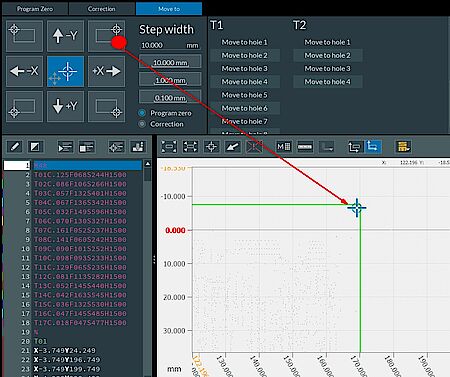

You can manually shift the program via the green program frame with the preset step width. The function is realized via die XY-buttons which can be found in all tabs of the page "Program Zero".

Additionally, the AOFF offset can be added in the tab "Correction".

Confirm the determined offset values with the Action button.

Move to Corner

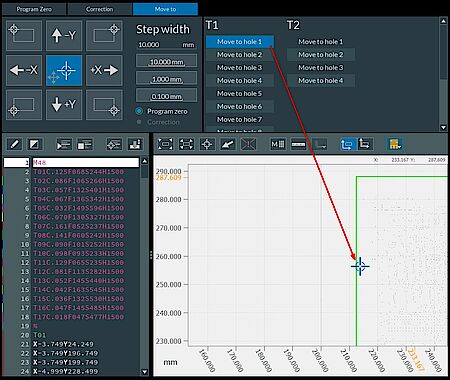

The determined program offset can be checked in the tab "Move to". The CNC is automatically moved to the defined corner of the maximum program area (s. green frame in the figure) to check the correct alignment of the board stack for execution.

During the movement the pressure foot is automatically retracted and the spindle is moved to the position of the defined corner. The diameter of the active tool in the spindle is considered for aligning the outer edge of the tool correctly. At this position the Z-axis is lowered to the H-plane to enable a more precise determination of the position.

Tracing

The tracing function can be activated in all tabs of the page "Program Zero". The benefit of this function is that the spindle of the selected work station is also moved during offset determination. The preset step width (s. "Step width" in the figure) can be individually adjusted in the context menu.

Offset Determination at a Glance in Tab "Move to"

It is possible to automatically approach individually programmed drill holes at the edge or the corners of the program area. The automated alignment function enables great time savings during program setup for manufacturing. This eliminates e.g. the manual determination of the correct work offset via CNC commands and Jog keys.