Automatic Deactivation of the Surface Contact

CNC News

A Feature in CNC 95.00

The function "automatic deactivation of the surface contact" was implemented in CNC 95.00 in order to simplify setup and execution for the end customer. The function applies to nibbling and drilling and ensures a quick and secure production through less operator interventions.

Function

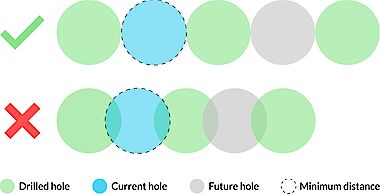

The function is activated with CNC command TOTD,Pp and a percentage value p is defined. The percentage value serves to calculate a circular minimum distance between drill holes, in which the surface contact can be evaluated. The minimum distance applies between the center of the new drill hole and all old drill holes.

The following applies to monitoring with TOTD,P:

- If a drill hole is located within the calculated minimum distance d, the surface contact won't be evaluated.

- If no drill hole is located within the calculated minimum distance d, the surface contact is evaluated.

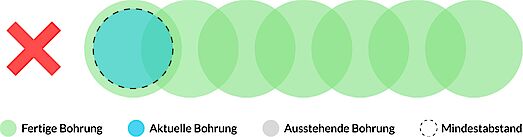

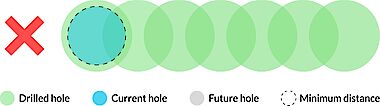

Example for a minimum distance of 100 %

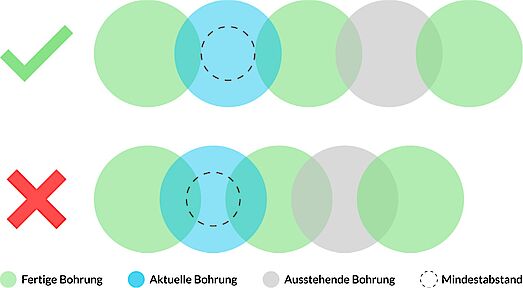

If the minimum distance is 100 %, the whole tool area is considered during monitoring. The surface contact is not evaluated, if old drill holes overlap with the tool area (s. figure).

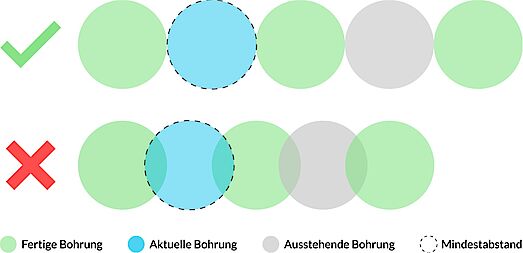

Example for a minimum distance of 50 %

If the minimum distance is 50 %, the central 50 % of the tool diameter are considered during monitoring. The surface contact is not evaluated, if old drill holes overlap with the tool center (s. figure).

Use case

In practice, the function is used to avoid contact drilling errors and speed up execution when e.g. cleaning nibbled slots.