Technical papers

The Best of Two Worlds

Technical papers

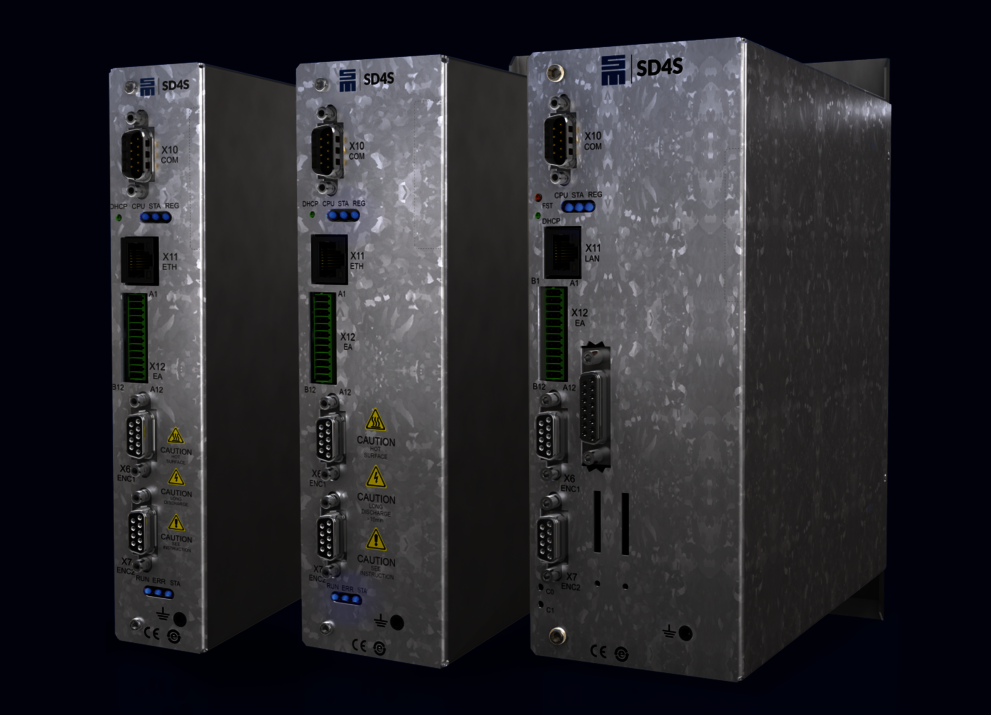

Minimal Motor Heating with High-speed Converters by SIEB & MEYER

Technical papers

Screw Tightening with Straightforward Control

Technical papers

Frequency Converters Improve the Climate Footprint

Technical papers

Optimal Operation of IPM Motors – with Frequency Converters of the SD4x Product Family

Technical papers

Frequency Converters: Past – Present – Future

DO YOU NEED MORE INFORMATION?

If you have any further questions, please do not hesitate to contact our press department:

Ms. Annika Ritari

PR, Media and Exhibitions

Phone +49-(0)4131-203 - 1381

E-Mail Annika.Ritari@sieb-meyer.de