SIEB & MEYER Supplies Power Electronics for the Green Energy Turbine (GET®) by DEPRAG

Technical papers

Because every kilowatt-hour counts

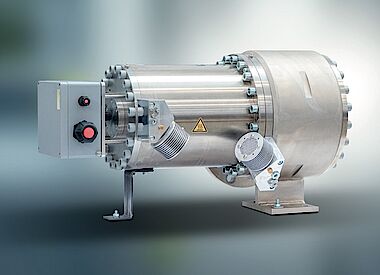

Energy conservation is the urgent need of our time. The Green Energy Turbine (GET®) by DEPRAG is used to recover even small amounts of residual or waste energy from different mediums and convert it into electrical energy. Drive controllers by high-speed specialist SIEB & MEYER ensure highly efficient and almost loss-free control of the generator.

Squeezing the last drops of toothpaste from the tube or even cutting the tube open, storing the ketchup bottle upside down in the fridge, licking the yogurt lid clean or shaking chip crumbs out of the bag: in the past, all this was called 'let nothing go to waste'. Today, we talk about sustainable action or management. Especially regarding thermal and electrical energy, we have learned since the winter of 2022/23 at the latest that wasting energy is not smart. This not only applies to consumption but also involves responsible use of residual or waste heat.

At this point, the Green Energy Turbine (GET®) by DEPRAG comes into play in two ways: on the one hand, it recovers (residual) energy of a medium in the form of heat or excess pressure and on the other hand, it directly converts this energy into electrical energy. "Originally, our main business areas were screwdriving technology and pneumatic tools," explained Stefan Freundorfer, product manager GET at DEPRAG Schulz GmbH & Co. KG. “We have developed a turbine motor for the latter. In cooperation with the university OTH Amberg-Weiden and the Center for Energy Technology (ZET) at the University of Bayreuth, we developed the current Green Energy Turbine – which is a turbine drive combined with a generator.”

The Green Energy Turbine is a turbo machine with axial or radial design and one or more stages. Using the expansion of a gas from high to low pressure at constant mass flow, this expander converts the available energy into electrical energy. The gas expansion occurs either in the jet (impulse turbine) or in the jet and turbine wheel (reaction turbine). The generated kinetic energy is converted into rotary motion, which in turn drives the generator.

Direct or indirect use

Basically, there are the following two application areas for the GET®: direct use and indirect use. With direct use, energy is recovered from pressure drop. For example, if compressed air, CO2 or another gas with excess pressure is available, the turbine can directly expand that medium and convert it into electrical current. With indirect use, unused surplus heat is converted into electrical current using a closed process called organic Rankine cycle (ORC).

For this purpose, a medium with low vaporizing temperature is compressed using a feeding pump and then heated in a heat exchanger with the available waste heat. Afterwards, the now gaseous medium is first expanded, then liquefied and compressed again using the GET®. "This closed circuit converts up to 20 percent of the heat energy into electricity," explained Stefan Freundorfer. "That means, for example, that 100 kW thermal power make about 20 kW electrical power."

From the individual project to series production

The Green Energy Turbine is available in the power range from 5 kW to 300 kW, both as an individual project and in series. "Our bestselling products have powers between 30 and 60 kW. However, in the range of 100 kW and more we are also seeing increasing interest," said Stefan Freundorfer. “The reason is that the price per kilowatt decreases as the power increases. Twice the power does not cost twice as much, just perhaps a third more. For the generator, we use a construction kit that covers different power levels. The turbine, we design individually – depending on medium, pressure and temperature amongst other properties.”

Application areas for the GET® are, for example, natural gas transfer stations, ship engines, geothermal and CHP units but also industrial processes generating waste heat that can be utilized via ORC. "The industries are diverse because almost everywhere heat is released unused to the environment in varying quantities and temperatures," emphasizes Stefan Freundorfer. "Even for small outputs, our turbine generator is available with a compact and robust design. In addition, the turbine works without gear between turbine and generator. The rotor of the generator rotates within the medium and therefore does not need to be sealed. All this makes the GET low-maintenance and perfectly suitable for continuous use."

Low losses when converting high-frequency AC voltage

The cooperation between SIEB & MEYER and DEPRAG started more than 20 years ago – initially in the field of screwdriving controls and later expanding to the field GET®. "In the beginning, we were looking for a power electronics solution suitable for high turbine speeds and correspondingly high generator frequencies," remembered Stefan Freundorfer. “Our turbine rotates with 11,000 to 40,000 revolutions. The frequency converter should be able to convert the resulting high-frequency AC voltage with low losses.”

Drive controllers by SIEB & MEYER provide the high clock frequency required for that purpose even in higher power ranges and at the same time keep the rotor heating low. The latter is important since the GET® rotor has roller bearings but no active cooling. The following products are used: SD2 and multilevel converter SD2M for higher power outputs. Soon, the latter will be available as updated version SD4M for the cooperation with DEPRAG. Both drive controllers provide a DC connection and enable energy flow in both directions when combined with a suitable power supply unit.

"For the generator to reach the required speed, it must first be accelerated by a motor," explained Ralph Sawallisch, key account manager drive technology at SIEB & MEYER. "That means, the energy flow is reversed in the beginning. Then, the GET® starts the thermodynamic process, opens the gas circuit and as a reaction feeds electrical current to the grid. Our drive controllers keep the specified speed, no matter in which direction the energy flows. In addition, they score with very good efficiency and short reaction times so that they can fulfill the control demands quickly."

Double know-how for unique solutions

Users of the GET® not only benefit from the drive controller features but also from the long-term cooperation and optimally matching technologies of both companies. Towards customers, DEPRAG and SIEB & MEYER act as duo. Both companies stay in close contact throughout all project phases. "No project is like another," said Ralph Sawallisch. “One application has unusual voltages, another works in demanding ambient conditions. And the next customer wants to expand natural gas so that we must consider explosion protection. In the face of all these challenges, we can practically draw on double the know-how and therefore find the perfect solution.”

DEPRAG also appreciates this and meanwhile uses almost only drive controllers by the Lueneburg-based high-speed experts. "We swear by SIEB & MEYER now," concluded Stefan Freundorfer. “The quality and functional spectrum of the converters as well as the product variety pay off for us. In addition, the service is excellent. Technical questions are answered quickly and competently and we also receive support with the documentation. The whole package fits.”

Conclusion

Due to rising energy costs and climate protection regulations the demand for technologies to improve energy efficiency is increasing. With the Green Energy Turbine (GET®) by DEPRAG, customers can utilize even small energy amounts from gases or processes. The new technology allows energy recovery in many industrial areas. Combined with drive controllers by SIEB & MEYER, the GET® brings users closer to their climate targets and also saves money.

About DEPRAG SCHULZ GmbH & CO. KG

DEPRAG currently employs 780 people around the world, 450 of them work in the company headquarters in Amberg (Germany). The family business managed by the third generation is a globally leading supplier for screwdriving and feeding technology, automation, air motors, air tools and solutions for energy recovery like Green Energy Turbine. Products of renowned manufacturers in the sectors automotive e-mobility, electronics, computer technology, household appliances, medical technology and many more are produced with assembly technology by DEPRAG.