SM IIoT Connect

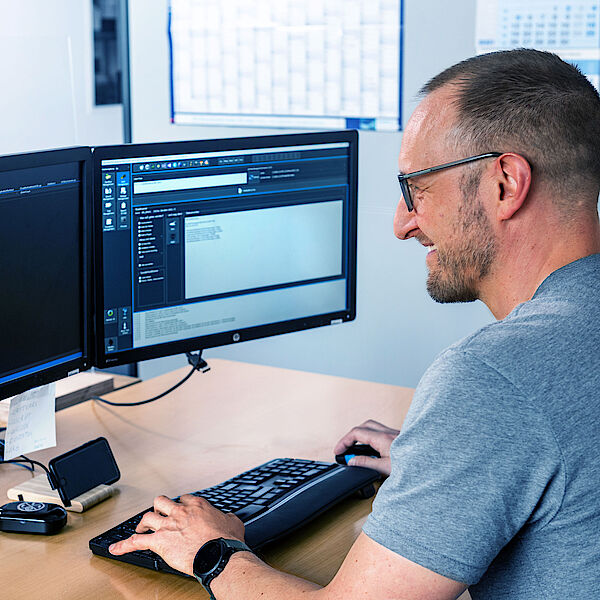

You can connect your drilling and routing machines quickly and easily to your IT systems via various interfaces. This enables you to access current and historical data or send data to the machine. In this way, communication with other participants such as sensors and machines is also possible.

Supported by:

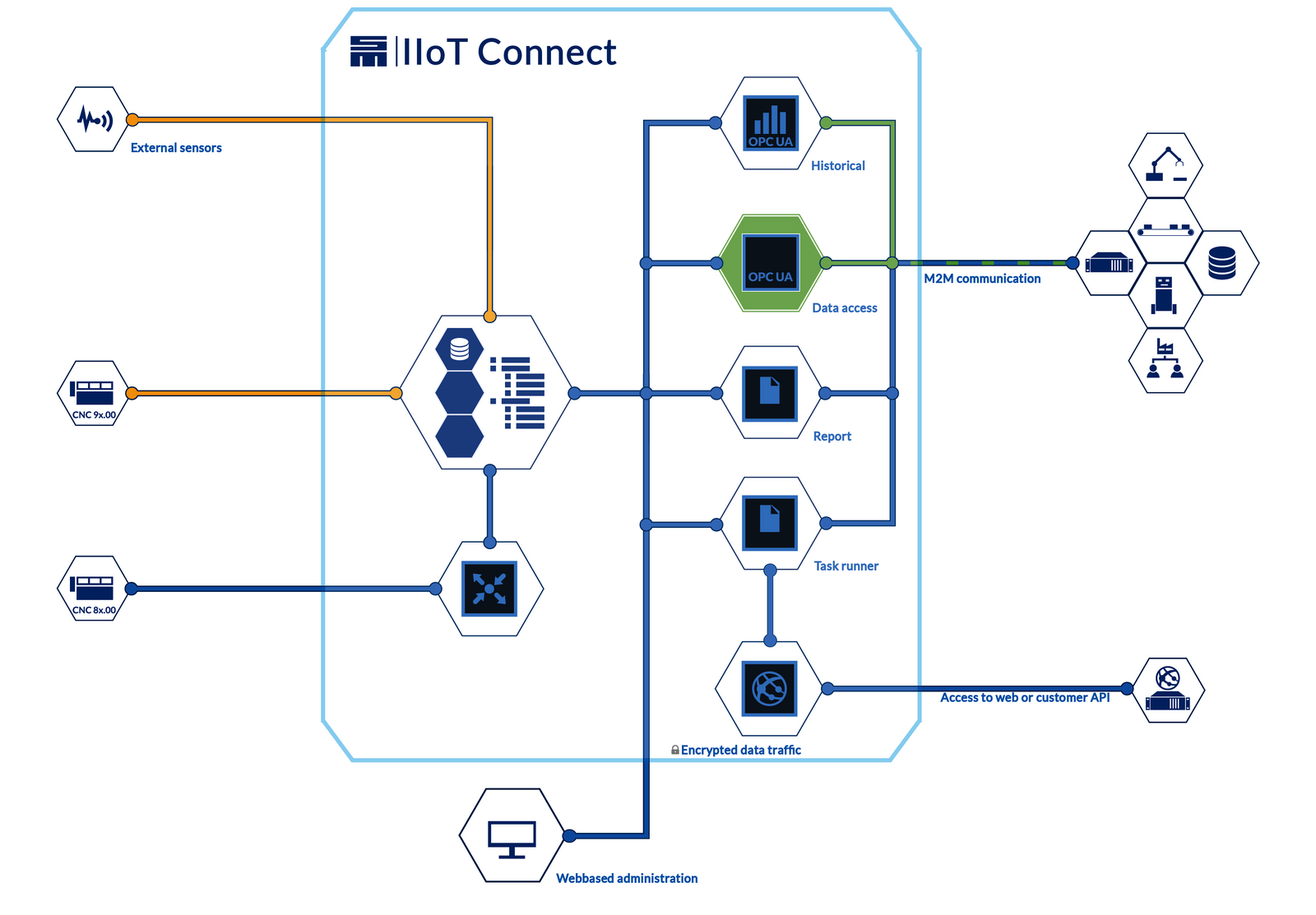

High Level Architecture

The components of SM IIoT Connect are interconnected via a central Service Bus. Thanks to a loose coupling of every component and the availability of different interfaces it is possible to implement a software solution that meets the demands of every production.

The data communication is secured against third parties by means of encryption. Encryption is ensured up to the control level.

Thanks to a OPC UA interface the control systems can communicate on the field level and exchange their information models and data.

- Security – Right management for data access via OPC UA

- Security – Communication encryption

- Edge Computing – Data processing and data storage on the PC

- Integration – Uniform handling of different CNC control generations

- Integration – Access to data and functions via different programming languages (Python, C++, C#)

- Reporting – Automatic report generation via IIoT-Pages

- Automation – Execution and Monitoring of external programs

SM IIoT Connect for CNC 95.00 and CNC 93.00

In the CNC 95.00/CNC 93.00, the OPC UA interface is always available as a modern and flexible solution.

SM IIOT Connect clearly displays all important production parameters and also enables the CNC 95.00/CNC 93.00 to be automated via the standardised OPC UA interface. For example, part programmes can be loaded, CNC commands can be sent to the control or processing can be started or stopped.

SM IIoT Connect for CNC 84.00 and CNC 82.00

With SM IIOT Connect, standard in the CNC 84.00/CNC 82.00 since 2021, the OPC UA server is available as a modern alternative to the previous SMDDE protocol.

The new information model clearly displays all important production parameters and also makes it possible to automate the CNC 84.00/CNC 82.00 using the standardised OPC UA interface. For example, part programmes can be loaded, CNC commands can be sent to the control or processing can be started or stopped.

Feel free to contact us

![[Translate to Englisch:] SM IIoT Connect](/fileadmin/_processed_/2/f/csm_Produkt_Teaser-1000x1000_Plattform_64b019ae92.png)

SM IIoT Connect

You can connect your drilling and routing machines quickly and easily to your IT systems via various interfaces. This enables you to access current and historical data or send data to the machine. In this way, communication with other participants such as sensors and machines is also possible.

Supported by:

High Level Architecture

The components of SM IIoT Connect are interconnected via a central Service Bus. Thanks to a loose coupling of every component and the availability of different interfaces it is possible to implement a software solution that meets the demands of every production. The data communication is secured against third parties by means of encryption. Encryption is ensured up to the control level. Thanks to a OPC UA interface the control systems can communicate on the field level and exchange their information models and data.

• Security – Right management for data access via OPC UA

• Security – Communication encryption

• Edge Computing – Data processing and data storage on the PC

• Integration – Uniform handling of different CNC control generations

• Integration – Access to data and functions via different programming languages (Python, C++, C#)

• Reporting – Automatic report generation via IIoT-Pages

• Automation – Execution and Monitoring of external programs

SM IIoT Connect for CNC 95.00 and CNC 93.00

In the CNC 95.00/CNC 93.00, the OPC UA interface is always available as a modern and flexible solution.

SM IIOT Connect clearly displays all important production parameters and also enables the CNC 95.00/CNC 93.00 to be automated via the standardised OPC UA interface. For example, part programmes can be loaded, CNC commands can be sent to the control or processing can be started or stopped.

SM IIoT Connect for CNC 84.00 and CNC 82.00

With SM IIOT Connect, standard in the CNC 84.00/CNC 82.00 since 2021, the OPC UA server is available as a modern alternative to the previous SMDDE protocol.

The new information model clearly displays all important production parameters and also makes it possible to automate the CNC 84.00/CNC 82.00 using the standardised OPC UA interface. For example, part programmes can be loaded, CNC commands can be sent to the control or processing can be started or stopped.

About Sieb & Meyer

SIEB & MEYER AG - Drive and control solutions of the latest generation

SIEB & MEYER was founded in 1962 and is a successful company in the field of industrial electronics. With around 300 employees worldwide today, we develop and manufacture control technology and drive electronics. Our core technologies include controllers for mechanical engineering and automation technology, servo amplifiers for a wide range of drives and frequency converters for high-speed motors and generators.

Contact

SIEB & MEYER AG

Auf dem Schmaarkamp 21

D-21339 Lüneburg

Phone: +49 4131 203 0

Fax: +49 4131-203 2000

You can find all sales contacts at: www.sieb-meyer.com/contact/sales

You can find all agencies and partners at: www.sieb-meyer.com/contact/offices-and-sales-partners